Artificial intelligence (AI) and machine learning (ML) in power electronics build on the existing foundation of digital power and represent the next step in the evolution of power converter design, control, and optimization. Just as digital power enables more complex control algorithms than analog control techniques, AI and ML will allow even more complex and dynamic non-linear control surfaces to enhance efficiency, reliability predictions, and health monitoring in power converters. This FAQ begins by briefly looking at the growing interest in AI/ML for power electronics applications, it then presents two examples of using AI/ML, one for grid-tied solar installations and one for motor drives, and it closes with a review of some of the challenges to the wide-spread application of AI/ML in power electronics.

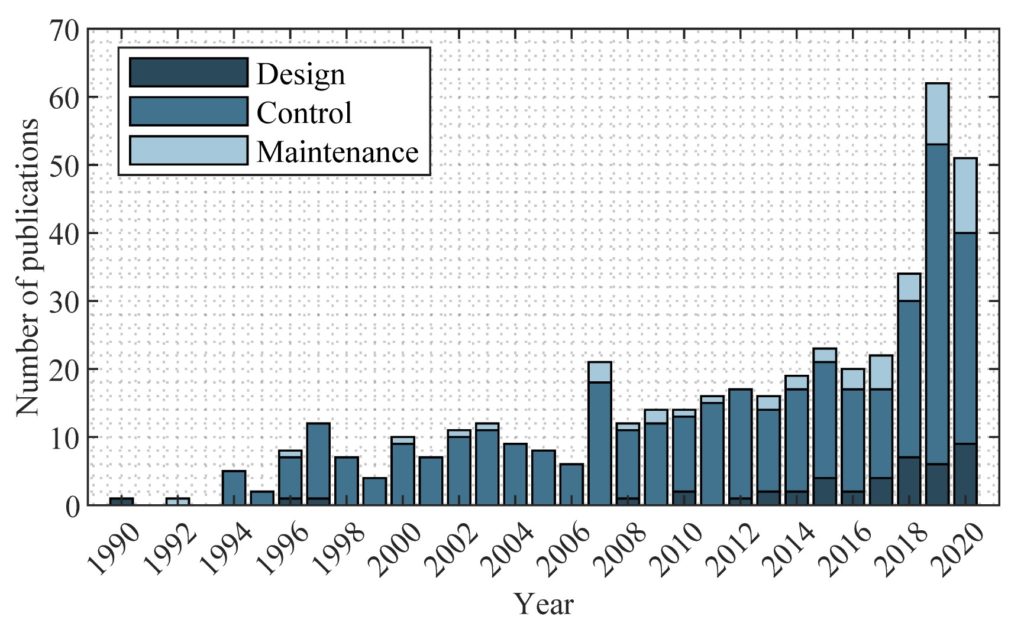

Power converter designers and power semiconductor companies are actively developing AI/ML technologies. Research and development activity related to AI in power electronics is exploding (Figure 1). The application of AI/ML in power electronics is different from its use in more established areas such as image classification, speech recognition, etc. Power converter design, optimization of control loops, and preventative maintenance are three key areas where AI/ML are being used.

Grid-tied solar and AI

A convergence of developments, including lower-cost, high-performance computing resources, improved AI tools, and increasing amounts of relevant data sets, are driving the growing use of AI/ML in photovoltaic (PV) systems, especially in grid-tied PV. AI is being used to improve PV systems’ design, forecasting, control, and maintenance, resulting in improved return on investment for system owners and operators. In addition, AI is being employed to improve the cyber security of grid-tied PV systems increasingly connected to the cloud (Figure 2).

In the near future, value maximization of PV systems will increasingly rely on an AI architecture based on a synergy between the device (individual inverters), the edge (PV system/array controls), and the cloud (for continued AI training and ML support):

Device: high-precision real-time data collection capabilities will be added to PV inverters. That data collection will serve multiple purposes. It will enable the use of AI algorithms for real-time control of string-level energy yield optimization, real-time response to grid-tied control, and DC arc detection, based on real-time AI inference, execution, and self-closed-loop control capabilities. The data will also be sent upstream to the Edge and Cloud to support ML activities.

Edge: PV array controllers will benefit from the addition of ML capabilities that will support continual improvements in optimizing power generation and enabling higher levels of grid-interactive features. Like the device-level inverters, these controllers will collect data in real-time for AI inference engines (possibly based on fuzzy logic) and send the data to the cloud for more advanced ML functions.

Cloud: An AI/ML training and inference engine in the cloud will implement continuous training and optimize the AI algorithms on the Device and Edge, minimizing the need to add expensive computing power. In addition, AI/ML training in the cloud may have access to extensive data sets composed of inputs from multiple PV installations. Combining the data from multiple installations may yield even higher accuracy in AI inference engines at each location. The inference models on the device and edge will be updated in batches, achieving efficient collaboration.

Traditional PV inverter controllers are based on proportional-integral (PI) and proportional-resonant (PR) based algorithms. When AI algorithms are added to the controller, the response time of the inverter to transient errors and the controller’s accuracy can both be improved. In addition, AI-based inverter controllers can reduce THD in the output waveform. A variety of approaches are being developed for PV inverter control, including fuzzy logic control loops and fuzzy logic specifically for tuning the PID controller for improved robustness. More advanced techniques such as artificial neural networks and adaptive neuro-fuzzy inference system (ANFIS) based inverter controllers are also being researched.

Auxiliary resonant commutated pole topology

The auxiliary resonant commutated pole (ARCP) topology was proposed in the late 1980s to reduce switching losses in a zero-voltage switching (ZVS) and/or zero-current switching (ZCS) converters. However, conventional ARCP ZVS implementations could not maintain stability across the load, temperature, and manufacturing variances.

More recently, the stability challenges related to ARCP implementations were revisited using concepts borrowed from AI as applied in robotics applications. ARCP control systems lend themselves to AI implementations because the system operates in a noisy environment with limited access to parameters leading to a large degree of uncertainty, and since the system can never deliver control signals in real-time, the system must ‘pre-act’ based on a statistical and predictive AI algorithm.

In a practical implementation, an ARCP circuit is used for each phase leg in a power converter (Figure 3). ARCP can be used with IGBT as well as SiC/GaN MOSFET-based converters. The auxiliary resonant switches A1 and A2 are low-cost IGBTs that need to conduct about 1.5-times the peak load current, but with a duty cycle of only 1-5% and only need to be pulse rated. Capacitors C1 and C2 are also small, low-cost devices with capacitances between 10X and 200X the Miller capacitance of the main power switches (S1 and S2).

The ARCP control algorithm uses a hysteretic error calculation developed offline and ‘scores’ a switching transition and adjusts for the next switching cycle. If the control loop is fast and tight, the algorithm does not require complete knowledge of the operating parameters. The algorithm ‘pre-acts’ by driving the gates of the power switches based on a prediction of relative signals on a cycle-by-cycle basis. The relatively low switching frequencies of motor controllers are an important factor enabling AI techniques in ARCP control.

The pre-acting ARCP control algorithm has several performance benefits, including about an 80% reduction in IGBT switching losses and a 95% reduction in SiC and GaN MOSFET switching losses; as well as reductions in electromagnetic interference (EMI), inverter dV/dt, and common mode currents in motor bearings. Instead of reducing switching losses, pre-acting ARCP control can enable increased motor inverter frequencies (about 5X faster for IGBTs and up to 20X faster for SiC and GaN MOSFETs) for the same converter efficiency. Increased inverter frequencies can improve motor efficiency. The higher switching frequencies result in reduced output ripple in the current powering the motor, which reduces iron losses, enabling the motor to run cooler.

Challenges for development of AI for power electronics

Continued development and adoption of AI/ML in power electronic control applications will rely on improvements in dynamic performance and convergence speed, robustness, and generalization of AI/ML algorithms. Like early implementations of digital power, the computational burden is a significant challenge for AI/ML adoption. Today, expensive high-performance digital signal processors (DSPs) or field-programmable gate arrays (FPGAs) are required to implement AI/ML in power converters. Some of the AI/ML implementations being developed for power electronics are fuzzy logic, feed-forward neural networks, fuzzy neural networks, recurrent neural networks, and fuzzy neural networks, and reinforcement learning are some of the AI/ML implementations being developed for power electronics; each has distinct advantages and limitations (Figure 4).

Development of AI/ML algorithms that do not rely on expensive DSPs or FPGAs will be a key to the broad adoption of the technology in power electronics. Several possible paths to AI/ML for power electronics are currently being explored, including:

Data-light AI: Most AI/ML solutions require large datasets for optimal performance. In the case of power converters, the available datasets can be constrained, and the wide variety of power converter designs and operating environments often makes compiling large data sets impractical. The development of data-light in life and safety algorithms such as FFNN will be needed. The success of that development effort is expected to lead to spin-out benefits to non-power conversion applications of AI/ML that can benefit from less data-intensive processing.

Computation-light AI: Compared with image processing and other common AI/ML applications, there is no high-performance DSP or FPGA available in most power conversion systems. Real-time control is currently implemented using specialized and low-cost ICs. The development of computation-light control algorithms such as RNN and RFNN will be necessary to adopt AI in power converters. Effective partitioning of control and learning may be one of the keys. Implementation of learning techniques in the cloud may augment local AI controllers and provide more highly optimized performance with minimal computation demands.

Multilevel Information Fusion: The robustness of power electronic systems is essential, and it can be improved in AI/ML implementations using multilevel information fusion. AI/ML can be combined with the differential equations of power converter operation to derive a hybrid solution for condition monitoring, like fuzzy logic precisely for tuning the PID controller for improved robustness of PV inverters discussed above. The combined system would leverage the advantages of a model-driven side (the differential equations) and a data-driven side (AI/ML) for improved robustness and accuracy.

Summary

AI/ML for power electronics systems is building on over a decade of technology development for digital power. But the needs of AI/ML are far more computationally intensive compared with current digital power implementations. As a result, AI/ML for power electrics is starting in large high value-added applications such as renewable energy systems that can absorb the added costs more easily and in focused applications such as the ARCP control algorithm. The use of AI/ML in the broader power electronics industry will be dependent on the development of less resource-intensive techniques such as data-light AI, computation-light AI, and multilevel information fusion.

References

An Overview of Artificial Intelligence Applications for Power Electronics, IEEE Transactions on Power Electronics

A Review on Artificial Intelligence Applications for Grid-Connected Solar Photovoltaic Systems, MDPI energies

Making Auxiliary Resonant Commutated Pole (ARCP) Work, Pre-Switch

Optimal Transient Search Algorithm-Based PI Controllers for Enhancing Low Voltage Ride-Through Ability of Grid-Linked PMSG-Based Wind Turbine, MDPI