For the reactors used in the manufacture of LED’s there are more promising materials than the ones currently in use, the researchers point out.

There are many new possibilities for the development of gallium nitride (GaN) used in the production LEDs. One of the most promising production methods of gallium nitride is the ammonothermal method which uses a reactor filled up with liquid ammonia. The method is identical with the hydrothermal method utilised in the production of quartz, in which water is used instead of ammonia.

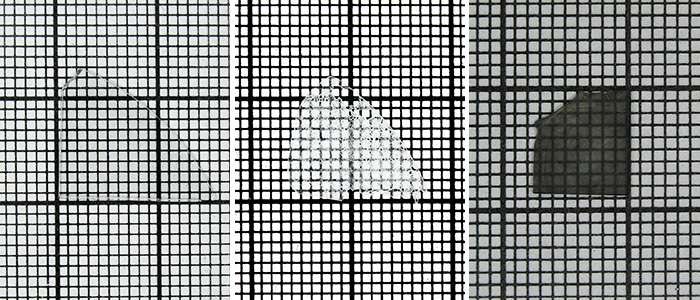

However, the high temperature inside the ammonothermal reactor combined with a pressure 2,500 times the atmospheric pressure and the corrosive effects of the so-called supercritical fluid pose a challenge to the reactor chamber and thus to the manufacture of LED materials. To find a solution to the problem, Aalto University Post-Doctoral Researcher Sami Suihkonen and a research group from the University of California, Santa Barbara led by Nobelist in Physics Shuji Nakamura and Post-Doctoral Researcher Siddha Pimputkar systematically analysed the behaviours of 35 metals, 2 metalloids and 17 different ceramic materials with 3 different supercritical fluid chemistries heated to a temperature of 572 degrees Celsius.

“In the ammonothermal method, the energy contained in the reactor corresponds roughly to a stick of dynamite, making the conditions fairly hostile,” saysSami Suihkonen.

“A nickel-chromium alloy commonly used in the reactors tolerates ordinary supercritical ammonia quite well but poorly withstands the effects of the mixtures used in the production of GaN which include the addition of ammonium chloride or sodium. Our research indicated that vanadium, niobium and tungsten carbide are stable in all three supercritical fluids. For practical applications, however, it is more important to find a material best suited for a certain type of chemistry. For ammonium-sodium this was silver; with ammonium-chloride, silicon nitride and noble metals appear the most promising.”

Higher quality materials with applications in power electronics

To replace the reactor’s nickel-chromium alloy with other structural materials would require the reshaping of the manufacturing process according to Suihkonen. More robust reactors would nevertheless enable the production of higher quality GaN containing fewer crystal defects which in turn leads to higher quality LEDs. Better LED quality translates to cheaper price.

“From a high-quality LED more light can be obtained per surface-area unit. As the price of an LED is governed by its surface area, better materials could reduce the price of LEDs to even a fraction of the current price Suihkonen calculates. Moreover, higher quality LED’s generate less heat and thus require smaller cooling elements, which could further reduce the price and enable LED lighting fixtures that are more compact than the current ones.”

Apart from their use in more economical and efficient illumination, these better materials could be useful also in power electronics, which is needed among other things, in power control of electric vehicles, in power supplies and converters.

The Stability of Materials in Supercritical Ammonia Solutions study was recently published in the Journal of Supercritical Fluids.