Camcon Automotive has built the first electronic engine valve system that is uncoupled from the crankshaft and offers control over the combustion cycle, according to New Atlas. An additional quirk to this is that it gives 4-stroke engines brief 2-stroke power boosts.

What differentiates Camcon’s system is it allows instant control over what the intake or exhaust valve is doing at any time, regardless of what the engine is doing. Camcon’s Intelligent Valve Actuation (IVA) system is fully electronic and has no mechanical attachment to the crankshaft.

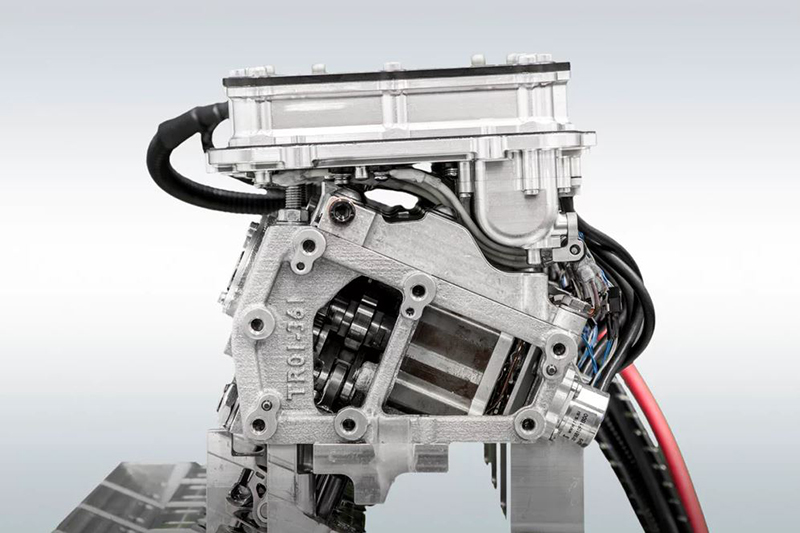

Each valve has its own camshaft that is controlled by an electronic motor. It also comes with a desmodromic system that opens and closes the valves. The motors can rotate fully to give 100 percent of the available valve lift, or they can even stop half-way through and go back to being closed. This allows you to get any degree of valve lift you want.

Additionally, the system know the position of the crankshaft due to the rotary position sensor. The entire system runs under real-time, closed-loop control, so each valve event is timed perfectly against the motor’s actions.

“What that means,” said Camcon COO Mark Gostick on a Skype call from his Cambridge office, according to New Atlas, “is we can give the engine exactly what it wants at low revs, and exactly what it wants at higher revs, and anywhere in between, and you don’t have to compromise at all. You can change timing, you can change duration, you can change lift, you can even shape the events if you want. You can do double events. You can change the profile of your camshaft between one event and the next. You can go from your idle setting to 100 percent throttle in one revolution. You can do pretty much anything. You’ve got what we like to call a digital crankshaft.”