Manufacturing safe and lightweight cars that emit less carbon dioxide could become easier thanks to a clever new engineering development from researchers at Hiroshima University.

Dr. Komgrit Lawanwong and colleagues have engineered some subtle refinements to metal forming techniques that allowed them to prevent a difficult problem called “springback,” which plagues the process of bending high-strength steel (HSS). Their results appear in the Journal of Materials Processing Technology.

High-strength steel is widely used in automotive structural components to help them withstand impacts without increasing their body weight. This has potential environmental benefits, as lightweight cars burn less fuel, and therefore have lower emissions.

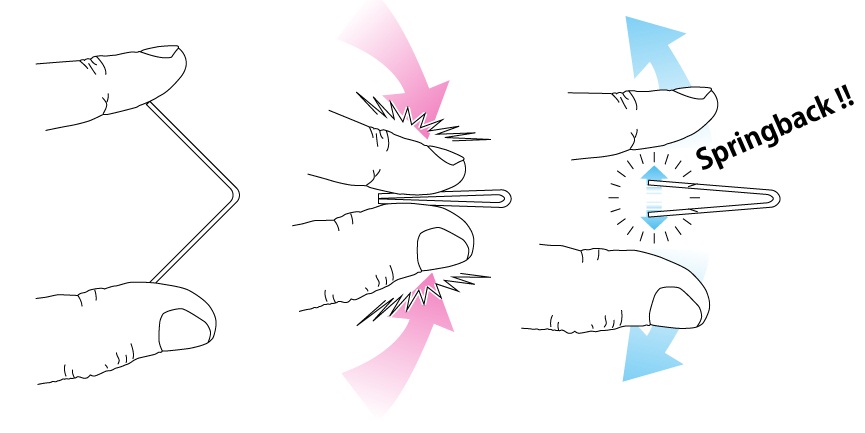

The most serious problem in the press-forming of these steel sheets is their extremely large ‘springback’—which is the tendency of a metal to return to its original shape after compression or stretching. A simple example of springback is the small gap that will remain if you fold a metal sheet in the middle with your fingers and then release it.

On an industrial scale, springback causes defects when metals are press formed.

“The problems become particularly acute when high-strength materials are used,” Dr. Komgrit said. “So a new technique to eliminate springback is urgently needed in the stamping industry.”

To make a U-shaped channel, three geometrical qualities are important, he explains: a precise bending angle with no springback, a sharp corner bend, and a flat bottom.

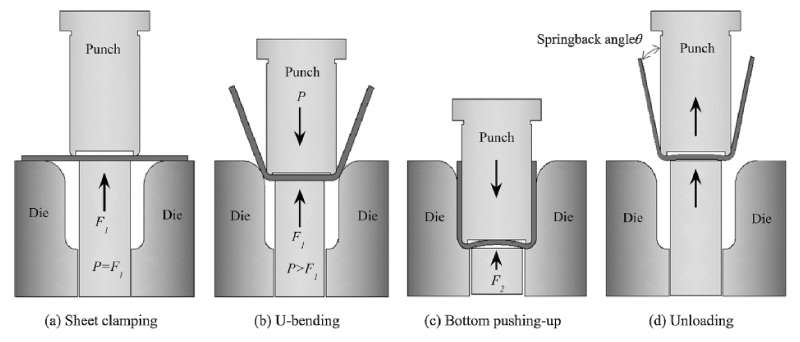

To avoid these problems, the Hiroshima group proposed a four-step process: clamping of a sheet between a punch and a counter punch; U-bending while maintaining constant clamping force; pushing up of the bottom section of the U-bend with a counter punch; and removing the sheet from the die. The new component of this process is the counterpunching.

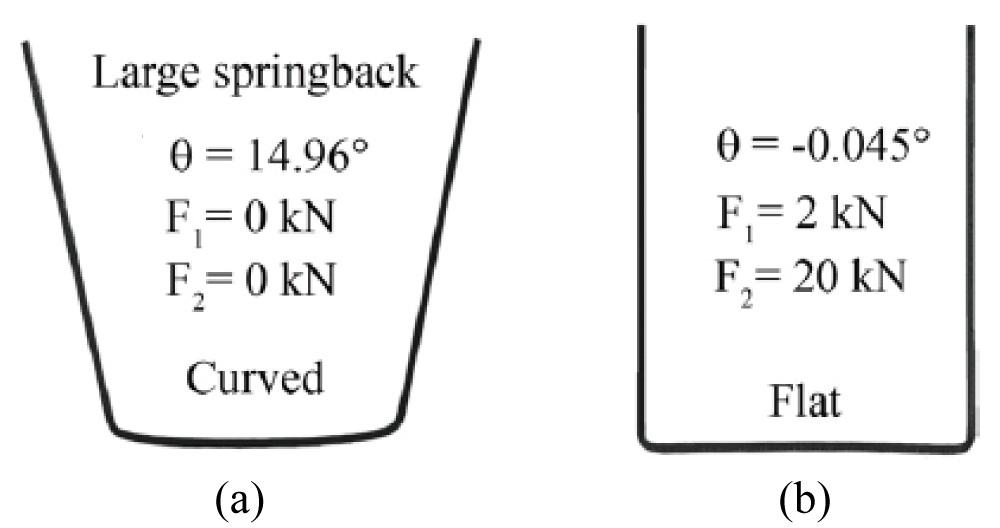

To study the effectiveness of this new technique the researchers compared it with the existing approach on 980Y steel—a high-strength metal. With the existing method, a large degree of springback was seen, and the bottom part of the U-bend remained curved.

“On the other hand, the new method delivered the best result for the springback angle—almost zero—together with a flat bottom,” the researchers note.

“Springback is becoming more of a problem as we try to use high-strength materials in many applications,” Dr. Komgrit said. “This method is a useful way to eliminate the springback of high-strength steel in press forming.”