Various forms of ambient energy are available in most environments. Depending on the environment and the power needs of the device, common energy harvester choices include light harvesters, thermoelectric harvesters, and mechanical vibration harvesters. Each of these energy harvesting technologies can be optimized for maximum performance in a given environment. In the case of light sand thermoelectric harvesters, this performance optimization is referred to as maximum power point tracking. For mechanical vibration harvesters, it is referred to as tuning.

Light energy

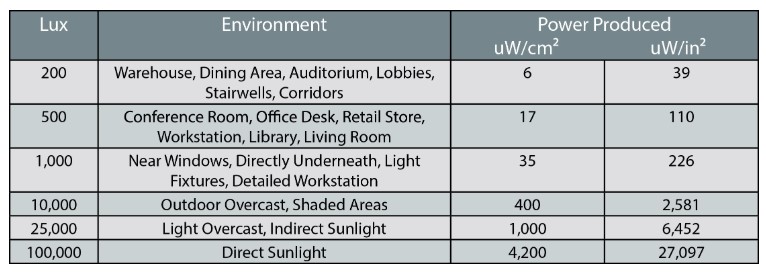

There are several technologies for harvesting light energy including conventional crystalline silicon solar cells, various forms of thin-film photovoltaic cells and dye-sensitized solar cells. Each of these light energy harvesting technologies offers a different set of performance tradeoffs. The amount (and wavelength characteristics) of available light energy varies widely depending on the light source and environment as shown below.

PV power production versus environment (source: Powerfilm Solar)

A solar cell, or photovoltaic cell, harvests energy by converting light energy directly into electricity using the photovoltaic effect. A single junction silicon solar cell can produce a maximum open-circuit voltage of about 0.5 to 0.6 volts. The majority of crystalline solar (c-Si) cells are used for large-scale energy production, such as on the roofs of buildings. These devices tend to be relatively heavy and not optimized for indoor energy production. As a result, they are not used in large numbers to power IoT nodes.

Thin-film solar cells are commercially available based on several technologies, including cadmium telluride (CdTe), copper indium gallium diselenide (CIGS), and amorphous thin-film silicon (a-Si, TF-Si). Thin-film technology has generally been lower in cost and lower in efficiency compared with conventional c-Si technology. However, the efficiency of these devices has significantly improved over the years. In certain designs, CdTe and CIGS efficiency is now beyond 21 percent, outperforming multicrystalline silicon. Some of the advantages of thin-film solar cells used to power IoT nodes include flexibility and lower weight.

Amorphous solar cells are more sensitive than crystalline solar cells. That results in two performance advantages when powering IoT nodes: They produce more energy in low light environments such as indoors or in non-ideal outdoor locations. And they have higher conversion efficiencies, so a smaller device can be used to produce a given level of energy.

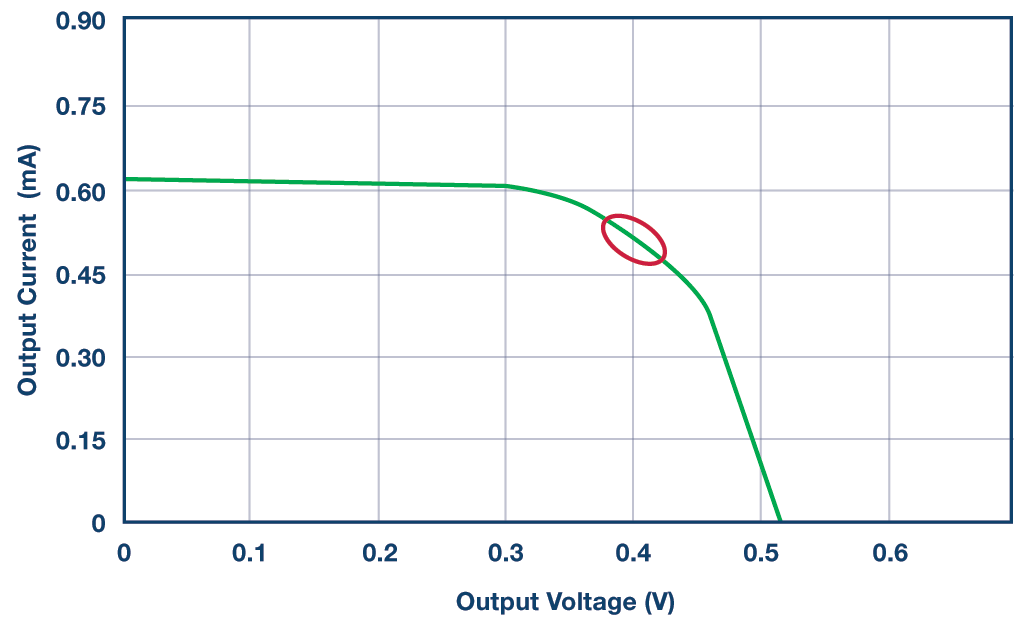

Both crystalline and thin-film solar cells require the use of maximum power point tracking (MPPT) to produce the maximum energy. Solar cells have a complex relationship between light irradiance, temperature, and total resistance that produces a non-linear output efficiency. The image below shows the output from a particular solar cell under one set of conditions. The red oval indicates the maximum power point. In a real operating environment, there would be a family of curves with varying MPPTs depending on the conditions.

Maximum power point for a typical PV cell (Source: Analog Devices)

Dye-sensitized solar cell (DSSC) technology is the newest light harvesting technology. Until recently, DSSCs have been based on a liquid structure using iodine and organic solvents and were not available as commercial products. Ricoh has introduced the first solid-state DSSC modules. Designed to generate electricity from indoor light, DSSC technology works by mimicking the photosynthesis process, replacing chlorophyll with light-absorbing dyes.

The new solid-state DSSC modules eliminate the safety concerns that kept the liquid-based DSSC from being developed into commercial devices. In addition, it achieves higher power generation efficiency under lower light levels, such as in warehouses, because the organic dyes used work most optimally with the wavelengths of indoor light sources.

Thermoelectric generators

Thermoelectric generators (TEGs) are solid-state heat engines made of pairs of p-type and n-type elements. The p-type elements are made of semiconductor materials doped such that the charge carriers are positive (holes) and Seebeck coefficient is positive. The n-type elements are made of semiconductor material doped such that the charge carriers are negative (electrons) and the Seebeck coefficient is negative.

Thermoelectric generator (TEG) construction showing heat and current flows (source: Electropedia)

The Seebeck effect refers to the creation of an electric potential across a temperature gradient. This potential difference is proportional to the temperature difference between the hot and cold ends and is used in TEGs to harvest thermal energy.

As illustrated below, the energy output of TEGs increases nonlinearly as the temperature differential increases. Since the temperature differential is rarely stable over time, any changes in the temperature differential mean that maximum power point tracking is needed to optimize the performance of TEGs.

Mechanical motion

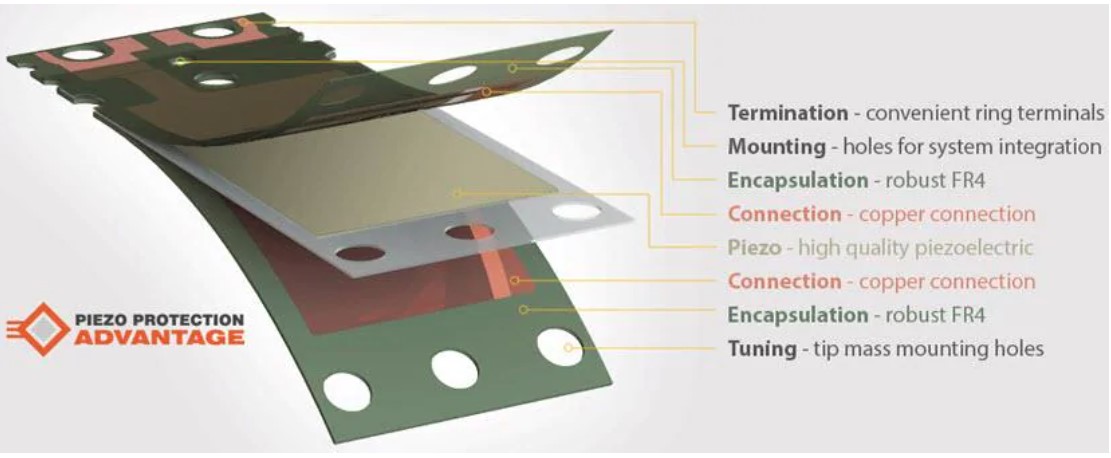

Mechanical motion harvesters are often found in industrial and transportation applications. The piezoelectric effect can be used to convert kinetic energy in the form of vibrations or shocks into electrical energy. Piezoelectric generators (energy harvesters) can offer a robust and reliable solution by converting normally wasted vibration energy to usable electrical energy. They are designed for use in applications that need to charge a battery, super capacitor, or directly power remote sensor systems.

Magnetic induction can also be used to convert mechanical energy to electrical energy. Magnetic induction refers to the production of a voltage in a changing magnetic field. This changing magnetic field can be created by motion, either rotation (Wiegand effect) or linear movement (vibration).

While both light and thermal harvesters use electronics to implement maximum power point tracking on a dynamic basis, mechanical harvesters are more limited. Mechanical harvesters are individually “tuned” to the dominant vibration frequency using a weight or series of weights that match the mechanical resonance of the harvester to the dominant vibration frequency to be harvested. In the illustration above, for example, the “Tuning mass tip mounting holes” are provided specifically for adding mass (weight) to the harvester to tune it to a specific vibrational frequency. Depending on the harvester design, mechanical tuning can be combined with an electronic MPPT circuit to further optimize power output.

Part three in this FAQ series, “Using Energy Harvesting to Power Wireless IoT nodes and Wearables,” considers various aspects of integrating energy harvesting devices into end products.

References:

Complete Solid-State Dye-Sensitized Solar Cell, Ricoh

Direct Conversion of Heat Energy to Electrical Energy, Electropedia

Electronic Component Solar Panels, PowerFilm Solar

Maximum Power Point Controller for Thermoelectric Generators to Support a Vehicle Power Supply, TU Berlin

New Advances in Energy Harvesting Power Conversion, Analog Devices