A few years ago, back when ordinary LED bulbs still sold for north of $10 a piece, there was a great brouhaha about LED light flicker. Light flicker can certainly be dangerous. Sufficiently intense flicker at between 3 and 70 Hz can cause epileptic seizure in a small percentage of the population. And flicker that isn’t visible can cause other problems. Perhaps most notably, fluorescent lamps that flicker at twice the ac mains frequency has been shown to double the average incidence of headaches in office workers and trigger migraines in some individuals.

Early LED bulbs got attention because some of them suffered from similar flicker problems. The problem mainly stemmed from the design of the LED bulb driver circuit. LEDs have a luminous intensity that is linearly proportional to the LED current, and they respond to current changes instantaneously. So any current ripple instantaneously becomes light flicker.

Inexpensive LED bulbs sometimes contained drivers that consisted of not much more than a capacitor in series with the LED string. Other inexpensive driver topologies that experienced flicker problems included those consisting of little more than a full-wave rectifier, and so-called ac-LEDs. The ac-LED approach uses two strings of LEDs powered in parallel with the anode of one paralleled string connected to the cathode of the other parallel string. One LED string lights up When the ac line voltage is positive, the other when the ac line voltage is negative. Thus only one of the LED strings has a current through it at any given time.

Pulse-width modulated LED drivers could also experience flicker problems. PWM drivers frequently serve as a drivers of LED bulbs meant to be compatible with dimmer switches. The flicker frequency for PWM dimming in LED bulbs typically is given by one over the period of the PWM waveform.

But since the early days of LED bulbs, flicker has become less of a problem. One reason is that LED driver circuitry has become more monolithic, reducing the cost of of fielding low-flicker bulbs. And more sophisticated driver techniques have emerged that minimize flicker. For example, some PWM-based drivers switch at higher frequencies to take the instantaneous dimming into the kilohertz range. And alternative approaches to dimming such as amplitude dimming have emerged where the current through the LED is continuous and not pulsing.

Meanwhile, the IEEE came out with a recommended practice for measuring LED flicker. In 2015, IEEE PAR1789 made recommendations on safe levels of flicker in LED-based lighting. The practice it recommends is to set allowable flicker equal to the flicker frequency multiplied by 0.8 and rounded up to the nearest whole number. Thus an LED with a 120 Hz flicker frequency would have a 10% maximum allowable flicker. (The IEEE spec recommended a maximum flicker percentage less than 0.0333 times the flicker frequency for special populations.)

The usual way of measuring flicker is with specialized photometers such as the Admesy Asteria SC-ASTR-01 High-Speed Illuminance Photometer which the DoE used for characterizing flicker. There are handheld versions of photometers available which tend to be priced in the $2,000 to $5,000 range. Viso Systems also made a photometer app for the iPhone at one time, but it has been taken off the market.

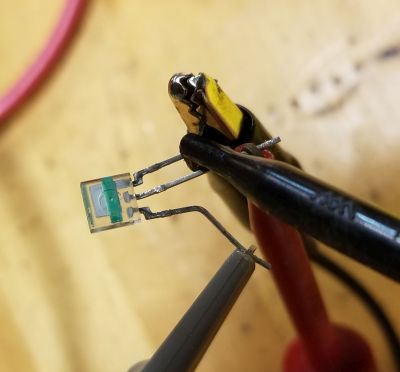

A less expensive approach to gauging LED flicker employs a combo photodiode/transimpedance amp chip connected to an oscilloscope. One device in this category is the Texas Instruments OPT101. Taos Inc. also made such a device (TSL257). It is no longer in production but can still be found online (as of this writing) from suppliers on eBay.

We used a Taos light-to-voltage converter to check out flicker properties of a few modern LED bulbs. We powered the IC from a 5-V battery pack to minimize the contribution of power supply noise to the output while monitoring the chip output with a scope. To see the flicker effects of a really bad LED driver, we first cobbled together a simple LED and series capacitor circuit which we plugged into the ac mains.

The Toas IC gave us a scope display of about 20 mV peak-to-peak at a 120-Hz flicker frequency riding on top of the chip’s dc output. It is interesting to note that this flicker wasn’t visible to the naked eye.

We then used the same setup to gauge the flicker of three brands of 60-W equivalent LED bulbs, one from Feit, another from Philips, and a third from Sylvania. All three of these bulbs are on the Consumer Reports best-buy list for LED bulbs.

In a nutshell, the results were anticlimactic. We were unable to see any flicker on our scope display for any of the three bulbs when

powered at full ac mains voltage. We also tested the three bulbs on a conventional wall dimmer switch employing the leading-edge phase principle. The Feit and Philips bulbs are both designed to be dimmed, the Sylvania bulb is not. And dimming didn’t affect flicker in either the Feit or Philips bulbs; it was still undiscernible on our scope trace. Not so for the non-dimmable Sylvania bulb, however. When dimmed to the lowest level on the switch, it pulsated visibly at a 10 Hz rate.

All in all, it looks as though the IEEE’s attention to LED flicker had the desired effect. Good quality LED bulbs these days don’t flicker unless you expect them to do something they aren’t designed to do.