Energy harvesting has been resonating in the industry circle as a technology fairytale for many years now. This environmental-friendly undertaking, that derives energy from external sources, thrusts on the industry scene with the promise of reducing our reliance on batteries. With a conservative approach toward power management, energy harvesting has been seen as revolutionizing many segments, ranging from home automation to wireless sensor networks and smart lighting.

Although questions may arise, such as where does energy harvesting technology stand today and why is it taking so long, the building blocks of an energy harvesting system must be explained first before delving into this tech wonderland and uncovering the stumbling blocks.

Energy Harvesting Building Blocks

Energy harvesting all starts with a device that extracts and manages small amounts of power from photovoltaic, piezoelectric, biochemical, thermal and mechanical vibration sources. The solar modules are most popular, because they are readily available. There are also piezoelectric and electromagnetic devices that generate power from kinetic energy sources like vibration.

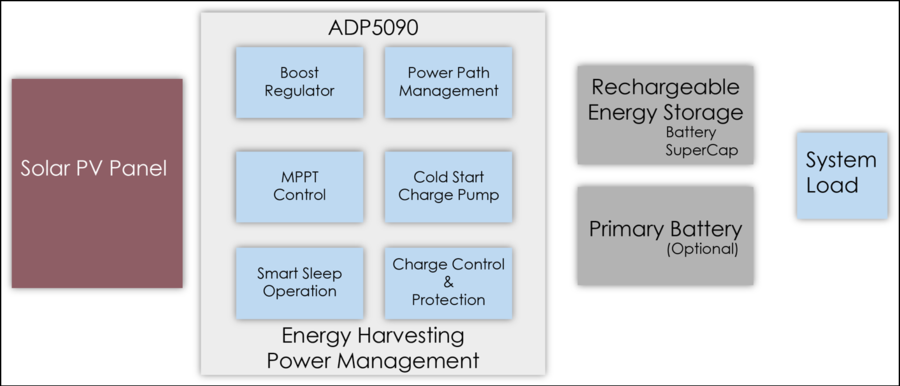

The second key building block is a power management IC that receives the lowest amount of power generated by the energy-harvesting device, and transforms that energy for storage in devices such as batteries or a supercapacitor. The power management IC also handles the outflow of power from the storage device, to ensure power is not being drawn when the stored energy is below a value of threshold.

The storage device in an energy-harvesting design—battery, conventional capacitor, supercapacitor, etc.—is connected to the rest of the system to provide the necessary power in order to operate an energy-harvesting application like a wireless sensor network.

Now, it is time to take a closer look at how these basic building blocks (Figure 1) work in tandem and what is actually hindering the potential of this technology.

New Design Challenges

For a start, it is worth acknowledging that energy harvesting systems have proved far more complicated than originally anticipated, mostly because of the issues related to power management and thermal management. Energy harvesting has added new design challenges of its own, for instance, the need for batteries that can operate for years without replacement.

Available batteries are typically undesirable due to size, cost, and reliability issues. In other words, energy-harvesting applications are not feasible with traditional battery-powered systems. The actual adoption has also been slow from the high cost of components mandating a new level of efficient energy management.

Energy harvesting’s slow take-off has been due to a confluence of several factors; however, recent changes have been made and the commercial realization of the Internet of Things (IoT) products is accelerating the development of MCUs, sensors, RF, analogs and other components for low-power electronics. As a result, the overall cost of implementing the energy-harvesting solutions is gradually decreasing.

The power management IC, a crucial part of the energy-harvesting design recipe, has quickly transformed in the IoT arena. The next section provides an overview of this power design transformation.

Power Management IC Makeover

What designers needed was semi-customized chips for energy-harvesting applications, not mobile chips merely repurposed for low-power applications. In other words, designers were looking for power management ICs that reduced the use and waste of primary batteries and made energy-harvesting devices power autonomously.

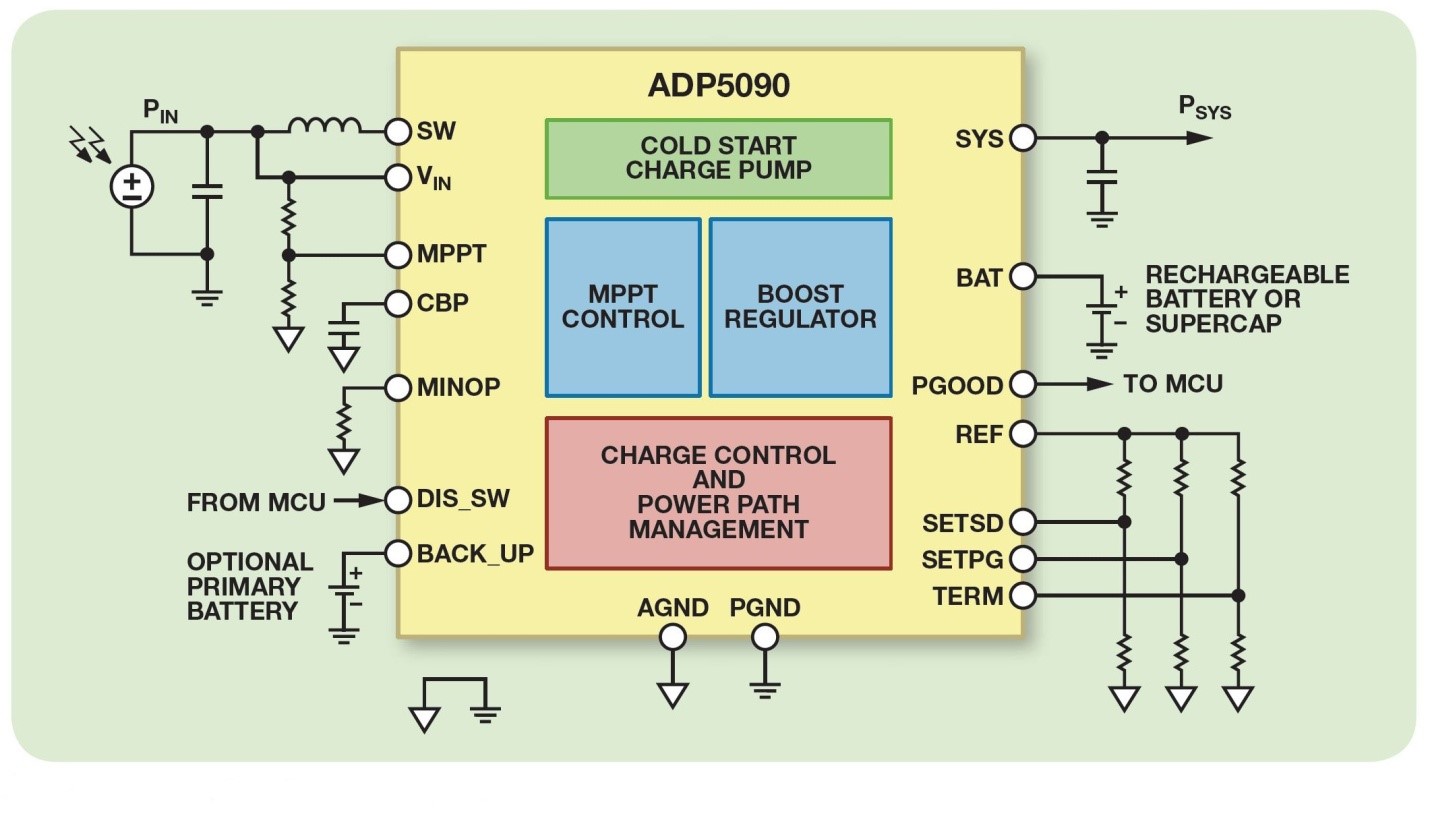

There has been significant progress in tailoring the power management ICs to energy-harvesting design requirements. The new chips, such as Analog Devices ADP5090 power boost regulator (Figure 3) maximize the efficiency of energy harvesting capabilities by using specialized techniques such as maximum power point tracking (MPPT), and thus guarantees the maximum power extracted from the energy-harvesting source.

There have been improvements in the energy storage front as well. Take the case of supercapacitors used to buffer and store power in energy-harvesting applications. The battery-backup devices, like supercapacitors, also provide charge to energy-harvesting systems when the battery is exhausted and there is no power supply available.

Leakage current is a critical issue in supercapacitors. When supercapacitors are applied to energy-harvesting applications to maximize power consolidation, energy wastage due to current leakage and power dissipation is not acceptable for designers.

Chipmakers like ALD are now offering power MOSFETs that compensate leakage current by lowering the operating voltage of the leakier supercapacitor. That way, MOSFETs automatically balance voltage in each cell and help facilitate ultra-low-power operation in energy-harvesting systems that otherwise take days to charge the required levels of current.

The above example of auto-balancing shows how low-power circuits are quickly improving. Add that to the advances in energy transducers and sensors, and what you see is energy harvesting quickly becoming feasible in places unimaginable just a few years ago. One such case is energy harvesting via a wireless sensor network.

Wireless Sensor Nets

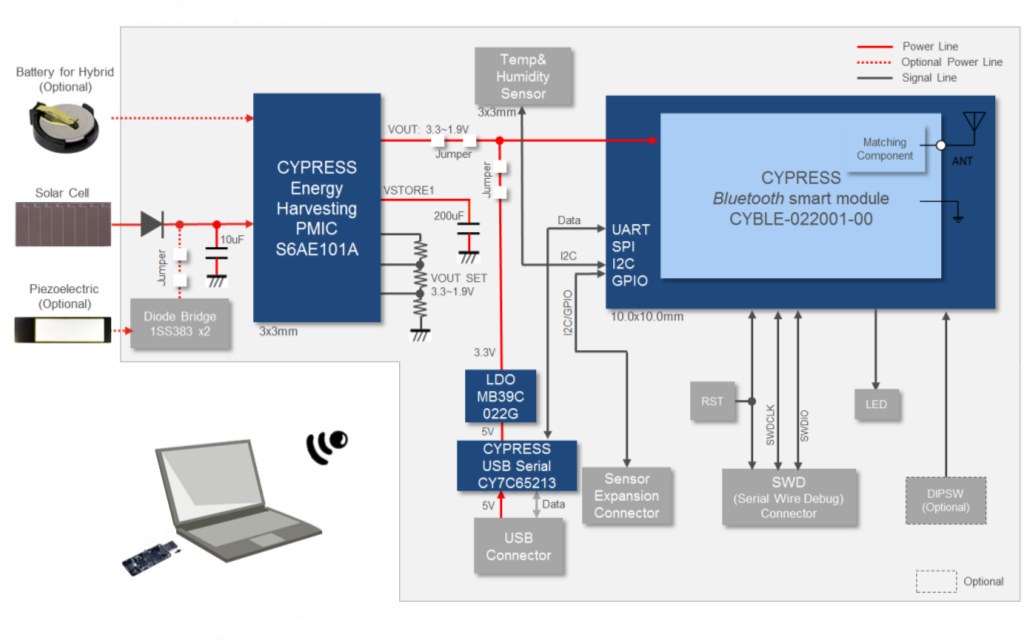

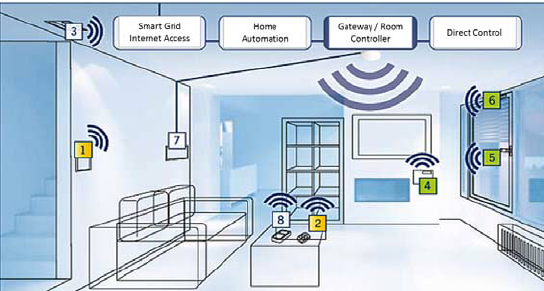

Wireless sensor networks used for smart lighting, home and building automation, remote asset monitoring and presence detection are classic examples of an energy harvesting application A wireless sensor node (Figure 4) can employ vehicle vibrations to power sensors on a bridge or use solar-powered sensors for wireless monitoring of a farm, factory or public utility.

A wireless sensor node—comprising a sensor, a microcontroller or microprocessor and an RF module—works in tandem with an energy harvesting system to create a complete monitoring application. The Japanese firm Murata claims that its wireless sensor node requires as little as 100 µW of energy to be harvested.

However, while engineers at Murata are confident that they are past the challenge of matching an energy harvesting device with a sensor node, they acknowledge that there are still hurdles to overcome.

Again, one of the key obstacles in the widespread use of wireless sensor nets has been the change of batteries. The development of chips consuming very little power, and the availability of battery-backup devices like supercapacitors, will allow energy harvesting systems in wireless sensor networks to operate for longer periods of time without battery changes.

Moreover, new power management ICs could help create batteries that can last 10 years or longer. Another critical factor benefiting energy harvesting applications such as wireless sensor nets is the advent of low-cost IoT gateways. These gateway devices maximize the efficiency of energy harvesting capabilities by offering more processing power at the network edge.

Conclusion

It’s apparent that IoT is providing the basic impetus for the energy-harvesting industry to turn the corner. Another way to see this intertwined technology relationship is that energy harvesting is rapidly evolving to meet the requirements for low power consumption in IoT systems. And that makes energy harvesting one of the key tenets of the IoT revolution.