That’s a complex and dynamic question without a simple answer. The electrification of everything is expected to lead to post-lithium-ion battery (LIB) technologies like potassium-ion batteries (PIBs), sodium-ion batteries (SIBs), and possibly more exotic chemistries. In the near term, the dominance of LIBs will be almost unassailable. The key word is “almost”.

Among the keys to replacing LIBs will be the ability of the contenders to offer improved sustainability in addition to matching the performance capabilities of LIBs. There is no single agreed-upon international definition of sustainability. That makes any discussion or analysis of sustainability problematic. Sustainability is often described in three dimensions related to environmental, economic, and social factors. This FAQ reviews some of the environmental and economic factors associated with the sustainability of LIBs versus SIBs with a glance at social factors and uses PBAs as an example of a highly sustainable rechargeable technology.

Effective recycling can be an important environmental consideration related to sustainability. For example, the materials in lead acid batteries (BPAs) are about 96 percent recycled, making them a highly sustainable technology. Looking at challengers to LIB’s dominance, SIBs are already being commercialized, while PIBs are mostly a work in progress.

Rechargeable batteries are a key technology supporting sustainable systems like electric vehicles and grid-scale energy storage. LIBs will continue to improve. But they are a mature technology, and it’s expected that the improvement rate for competitive chemistries like SIBs will be faster and eventually close the gap with LIBs. It’s not clear how rapidly any transition away from LIBs will occur. If it occurs, sustainability must compete with economic and technical performance considerations.

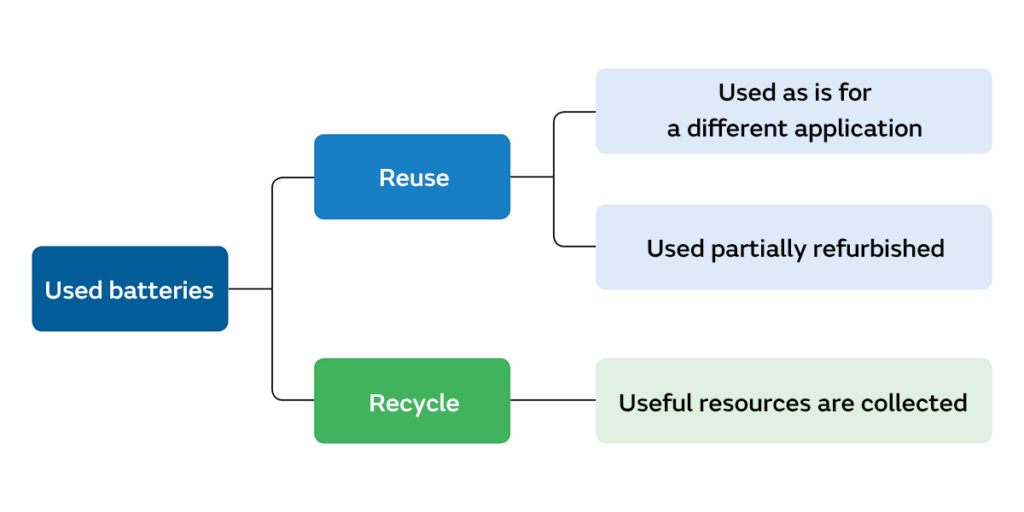

Japan is one of the leaders in maximizing the sustainability of LIBs and has developed multiple streams for using old LIBs, especially LIB battery packs in EVs. Even when EV battery packs no longer deliver the needed range, they can still have significant capacity. Sometimes, the battery packs can be refurbished for use in less demanding transportation applications, or they can be used in different applications like stationary energy storage, or they can be recycled (Figure 1). Recycling is well-established for PBAs but is not generally available for LIBs. Materials like plastic cases and metals are first separated when batteries are commercially recycled. With LIBs, the next step is to separate the cathode materials like lithium and cobalt; both are in very limited supply. Today’s challenge is that the cost of separating lithium and cobalt is too high compared to the cost of new materials. That’s one factor that makes it uneconomic to recycle LIBs.

Figure 1: In Japan, used LIBs can be reused or recycled to maximize sustainability. (Image Murata)

Standardized & simplified

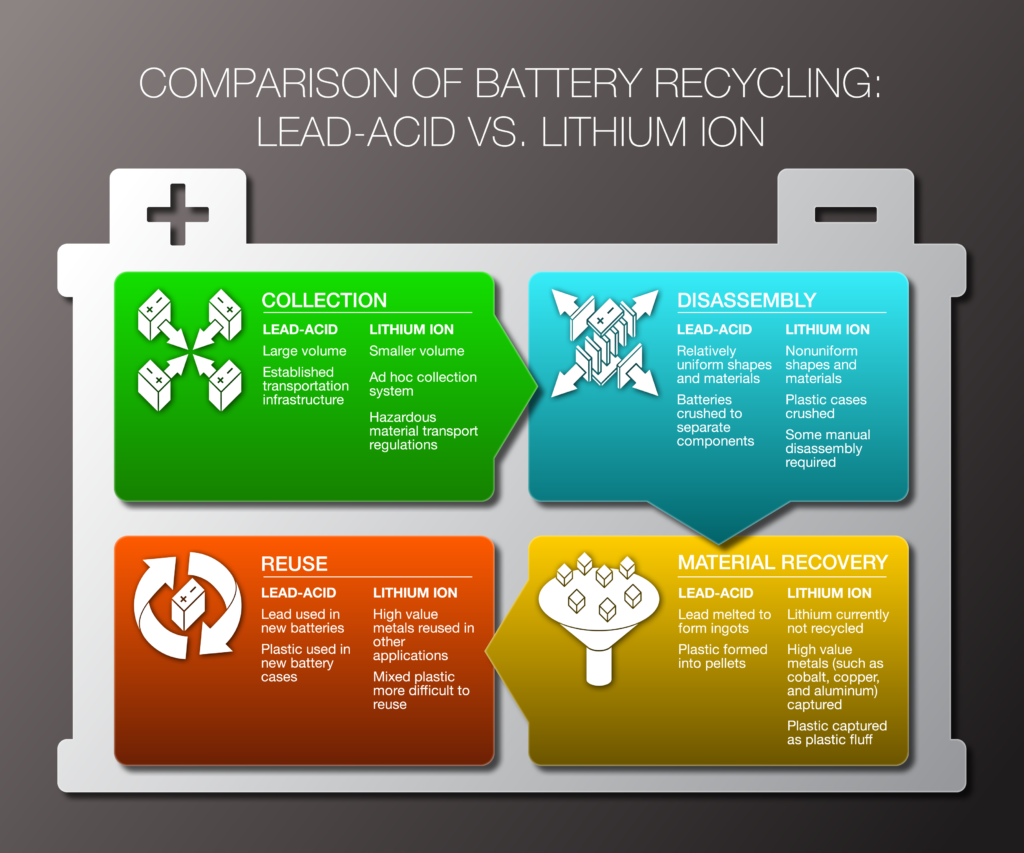

Among the challenges to effectively recycling LIBs are the wide variety of package styles and chemistries. PBAs have a much more limited range of package sizes and are mostly packaged in specific types of plastics. In addition, the lead grids are relatively easy to melt down and recycle. In contrast, many sizes and package materials are used for LIBs and a range of LIB chemistries, which significantly complicates any recycling processes. While there is also a wide range of SIB chemistries like sodium manganese magnesium oxide (NaMMO), sodium nickel manganese magnesium titanate (NaNMMT), sodium and iron-based Prussian blue analogs (NaPBA), and others, SIBs are generally easier to recycle compared with LIBs. But the materials’ low economic value limits the commercial recycling prospects.

SIBs are an emerging technology, and there’s an opportunity for the SIB industry to develop a limited range of package styles modeled after PBAs, reducing the cost of recycling SIBs and improving the economic equation of recyclability. The performance of NaPBAs is getting close to or even better than that of their LIB counterparts. As NIB performance rivals that of LIBs, sustainability may take a more central role in choosing between the technologies. Battery recycling can be envisioned as a four-step process (Figure 2):

- Collection

- Disassembly

- Material recovery

- Material reuse

Figure 2: Battery recycling is a four-step process that can help increase the sustainability of rechargeable batteries. (Image: EPRI Journal)

Effective LIB and SIB battery recycling technologies are still a work in progress. They will need to process ‘secondary’ materials like graphite, polymers, electrolytes, solvents, and salts in addition to recovering any higher-value materials. Several options are available, including removing organics and electrolytes using thermal processes and recovering other elements using pyrometallurgical or hydrometallurgical processes. Work under the European Battery Directive has identified hydrometallurgical processes as the most promising for recovering battery materials with the quality levels needed to support battery production and a circular battery economy.

Battery recycling processes must also be developed with sustainability and minimizing environmental impacts as key considerations. It does not necessarily increase sustainability if the recycling process results in large amounts of environmental damage. A comprehensive strategy for battery recycling requires that both the batteries and recycling processes be simultaneously optimized. This process is called “design for recycling”, which extends from the physical design and assembly of batteries to simplify recycling and increase yields and materials optimization to support cost-effective battery recycling processes (Figure 3).

Figure 3: Batteries need to be designed appropriately to maximize the benefits of recycling. (Image: CIC energiGUNE)

Alternatively, if economic recovery of key materials is not possible, battery recycling efforts should focus on minimizing the environmental impacts of battery disposal at end of life. That could require using different materials capture technologies and being supported with different battery designs. One study has found that recycling SIBs like NaMMO and NaPBA or the LIB LiFP with low material values may result in only limited environmental benefit. Of course, it’s not that simple, and the same study observed that with similar recycling rates, the toxic impact and resource depletion resulting from NaMMO, NaPBA, and NaNMMT SIBs use could be lower than most LIBs. Economics also matter. For example, today, the cost to capture lithium and cobalt from recycling LIBs is significantly higher than the costs of the mined raw materials.

Social sustainability

While difficult to quantify or place an economic value on, social sustainability can be an important consideration in the overall sustainability of products like rechargeable batteries. According to the United Nations Global Compact, “Social sustainability is about identifying and managing positive and negative business impacts on people. The quality of a company’s relationships and engagement with its stakeholders is critical. Directly or indirectly, companies affect what happens to employees, workers in the value chain, customers, and local communities, and it is important to manage impacts proactively.”

For example, the high level of PBA recycling came about partly due to the realization of the harm that lead causes to society in general if it gets into the environment, especially into the water supply. In the case of LIBs versus SIBs, SIBs currently appear to offer better social sustainability. Compared with obtaining sodium and the other elements for SIBs, mining lithium and cobalt for LIBs is fraught with negative environmental impacts and has been linked to alleged human rights abuses.

Design for sustainability

Designing for sustainability is the ultimate goal, but it can be challenging to achieve since the total environmental cost of producing and using rechargeable batteries is not assigned just to the design and manufacturing processes. There are multiple direct and indirect environmental impacts from rechargeable battery production, including high energy needed to produce the cells that result in greenhouse gas (GHG) emissions, resource depletion, and environmental impacts of mining the various materials and acidification of the local environment if the production process is not properly managed.

A life cycle assessment (LCA) can provide a starting point for systematically analyzing the impacts of rechargeable batteries throughout their entire life cycle. For example, an LCA for EV batteries includes the entire battery production process, how the batteries fit into the EV production process, environmental impacts from recharging the batteries over their useful lives, and the factors related to repurposing or recycling spent EV batteries (Figure 4). It’s a complex process. For example, lighter weight batteries need less energy to be carried as part of an EV, batteries with longer cycle lives can reduce the impact of repurposing or recycling the cells, batteries with higher charge cycle efficiencies can reduce the production of GHGs from recharging, and so on.

Figure 4: LCA for rechargeable batteries includes the production of the batteries, their integration into systems like EVs, and the impact of their lifetime use and recycling. (Image: Advanced Energy Materials)

Summary

So, are LIBs or NIBs more sustainable? The answer is still unfolding and will be impacted by numerous factors, including the changing costs of the materials used in both types of batteries, how cost-effectively the batteries can be repurposed or recycled, the social sustainability of each technology, and the total life cycle environmental impacts of LIBs versus NIBs. In any case, rechargeable batteries, especially post-lithium rechargeables, are expected to be major contributors to a more sustainable society.

References

Environmental Aspects of Grid-Scale Battery Deployment, Electric Power Research Institute

How do lithium-ion batteries contribute to the realization of a sustainable society?, Murata

Longer Lasting Sodium-Ion Batteries on the Horizon, Pacific Northwest National Laboratory

On the environmental competitiveness of sodium-ion batteries under a full life cycle perspective – a cell-chemistry specific modeling approach, Royal Society of Chemistry

Recycling of Lithium-ion Batteries: The Way for a Sustainable Energy Transition, CIC energiGUNE

Social Sustainability, United Nations Global Compact

Sustainable Electric Vehicle Batteries for a Sustainable World, Advanced Energy Materials