Wireless communication, 5G mmWave devices, space communications, GPS, satellites, space vehicle navigation, automobiles, and airplanes are just some applications for metamaterial antennas. Metamaterials are engineered/manmade materials with properties not found in nature. Antenna designs based on metamaterials can significantly increase the radiated power. The latest metamaterial antenna designs can radiate up to 95% of the input radio signal.

Conventional antennas need to be at least half the size of the signal wavelength to operate efficiently. At 300 MHz, for instance, an antenna would need to be half a meter long. In contrast, experimental metamaterial antennas are as small as one-fiftieth of a wavelength and could have further decreased in size. Some metamaterial antennas are already commercially available. This FAQ will briefly review some of the currently-available metamaterial antenna designs, including fractal antennas, electronically-scanned metamaterial antennas, and holographic beamforming, starting with high-resolution radar for automotive and defense systems.

Metamaterial-based antennas will offer higher performance levels beyond the restrictive efficiency-bandwidth limits of conventionally constructed antennas. Metamaterials enable miniature antennas with high gain since the radiating elements can be combined into larger arrays. In addition, the negative refractive index of metamaterials can result in focused electromagnetic radiation rather than dispersed radiation.

3D radar and scanned arrays

Metamaterial electronically scanned array (MESA) radar can be reduced from vehicle-mounted systems to a paperback book’s size with a comparable reduction in cost. Some of these radars can be manufactured with standard PCB fabrication technology and be used in a variety of new applications where today’s conventional electronically-scanned array (ESA) radars are too large and too expensive. These cost/performance attributes open up applications for MESAs in drones and other unmanned aerial vehicles, autonomous ground vehicles (including automobiles), portable security systems, and for countering threats from unmanned air systems (UAS), including complex environments with drones, cruise missiles, aircraft, and ballistic missiles.

Some MESA radars include software-defined radar technology and 3D electronic beam steering. For example, one 77GHz MESA radar with beam steering can accurately determine the range and speed of objects; it also has sufficient resolution to enable artificial intelligence to classify and interpret the surrounding environment with high precision.

Metamaterials for mmWave antennas

In natural materials, properties such as magnetic permeability and electric permittivity are determined by atoms and molecules’ response to the electromagnetic wave passing through them. But in metamaterials, these properties are determined by the periodic arrangement of scattering structures smaller than the wavelength of the electromagnetic waves they are interacting with.

These small structures are fabricated from conventional materials such as metals and plastics. Still, their size, shape, orientation, and configuration can be designed to interact with electromagnetic waves to create finely tuned resonances and other unconventional properties in certain frequency bands. These special properties can be used for a wide variety of applications, for example, to enhance the efficiency and directivity of microwave antennas.

A recently-developed electronically-scanned antenna technology, called metamaterial surface antenna technology (MSAT), is based on a diffractive metamaterials concept and achieves electronic scanning using high-birefringence liquid crystals (LCs). These antennas provide high reliability, low power consumption, and high data throughput for broadband Internet connectivity on moving vehicles or fixed installations. MSAT’s low power consumption allows it to leverage existing power on mobile platforms, reducing integration complexity.

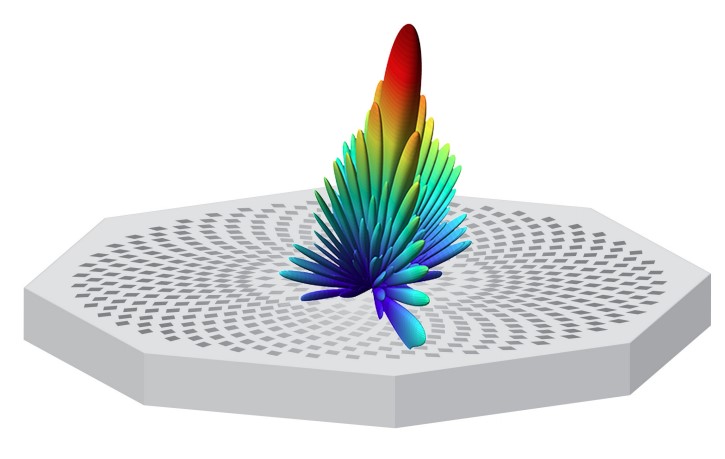

The use of LC materials as a tunable dielectric at mmWave frequencies permits over 60° beam scanning with under 10W of power consumption and an antenna thickness of about 5cm with no moving parts. As noted, an MSAT uses a diffractive metasurface, rather than a refractive one, to holographically define the antenna beam. The ability to individually tune each antenna element’s resonance frequency to create a dynamically reconfigurable diffraction grating enables the implementation of the holographic design.

Metasurface antennas have been fabricated by printing hundreds or thousands of elements into an array. The array is placed next to a rectangular waveguide feed that couples the array to a single transmitter. Computer control is used to tune the elements to resonate at a specific frequency and radiate the guide wave. The array’s physical structure is designed so that the radiated waves are coherent (in-phase) at the programmed scan angle of the antenna beam. The amount of energy is the sum of the waves radiated by the individual elements. The elements that are out of phase do not contribute to the signal. The scan angle is the angle between the beam and an axis perpendicular to the top of the metasurface antenna.

Holographic beamforming

Holographic beamforming also shapes the antenna’s radio pattern under software control without the need to physically change or reconfigure the antenna. It can be considered to be a software-defined antenna.

Conventional phased arrays need bulky and expensive phase shifters to control antenna beams dynamically. MIMO systems, in which two or more transmitters and receivers coordinate to beam signals into multiple devices, require power-hungry digital signal processors. New metamaterial-based holographic beamforming antennas use simple switched control antenna elements controlled by FETs, resulting in thinner antennas with lower cost, lighter weight, and lower power consumption.

Holographic antennas are expected to operate from about 500MHz to 60GHz. Signals can travel further with higher gain using holographic beamforming. In the case of 5G networks, that means that the mmWaves in the higher frequency bands will not be blocked as easily by buildings and could travel farther than a few kilometers. As a result, holographic beamforming antennas boost throughput for cellular networks and possibly replace fiber optic cables as backhaul links between base stations.

One form of metamaterial holographic antennas consists of a flexible PCB covered in metal cells smaller than the wavelength of the radio waves being controlled. The control software activates various antenna elements to create beams of radio waves. A changing dc bias is used to change the antenna’s properties, which can switch the controlled elements in a microsecond. This method of control enables the same spectrum band to be sequentially directed in multiple directions, allowing the same spectrum band to be used by multiple beams at the same time. In addition, the antennas suppress side-lobes that could result in interference, improving spectral efficiency (the amount of data that can be sent to a given number of devices simultaneously).

The series of FAQs includes both current commercial examples and research and development activities related to metamaterials. You might also be interested in reading the first FAQ in this series, “Metamaterials’ potential for transforming electronics.” The next FAQ will dive into “Metamaterials for power and energy.”

References

Metamaterial antenna, Wikipedia

Metamaterial-surface flat-panel antenna technology, Kymeta

Reducing 5G Deployment Costs Using Holographic Beam Forming Repeaters, Pivotal Commware