Because today’s battery management systems (BMS) are wired, the common source of cable failures – wire harnesses and connectors – becomes a warranty and functional safety issue. With the launch of a wireless BMS that features the first independently assessed functional safety concept, Texas Instruments hopes to revolutionize electric vehicle (EV) BMS. By removing the isolated connectors and bulky wiring, the entire system reliability can be greatly improved.

TI’s solution for wireless BMS empowers automakers to reduce the complexity of their designs, improve reliability, and reduce vehicle weight to extend driving range. With the flexibility to scale designs across production models, automakers can advance to production faster with TI’s comprehensive wireless BMS offering, including the SimpleLink 2.4-GHz CC2662R-Q1 wireless microcontroller (MCU) evaluation module, software and functional safety enablers such as a functional safety manual; failure mode and effects analysis (FMEA); diagnostic analysis (FMEDA); TÜV SÜD concept report; and more. To learn more, read the blog post, “More mile

TI’s solution for wireless BMS empowers automakers to reduce the complexity of their designs, improve reliability, and reduce vehicle weight to extend driving range. With the flexibility to scale designs across production models, automakers can advance to production faster with TI’s comprehensive wireless BMS offering, including the SimpleLink 2.4-GHz CC2662R-Q1 wireless microcontroller (MCU) evaluation module, software and functional safety enablers such as a functional safety manual; failure mode and effects analysis (FMEA); diagnostic analysis (FMEDA); TÜV SÜD concept report; and more. To learn more, read the blog post, “More mile

“The implementation of wireless battery management systems will be a growing trend in the EV marketplace because these advancements provide greater flexibility of design while also lowering the complexity and cost relative to traditional systems,” said Asif Anwar, director of the powertrain, body, chassis and safety service at Strategy Analytics. “By demonstrating a solution that combines these advantages with ASIL D compliance, the TI solution sets a benchmark for the industry to follow.”

To speed automakers’ development time, TI requested that TÜV SÜD, the industry’s leading functional safety authority, independently evaluate the quantitative and qualitative error-detection performance as well as the feasibility for automakers to achieve Automotive Safety Integrity Level (ASIL) D, the highest level of International Organization for Standardization (ISO) 26262 certification, using TI’s wireless BMS functional safety concept.

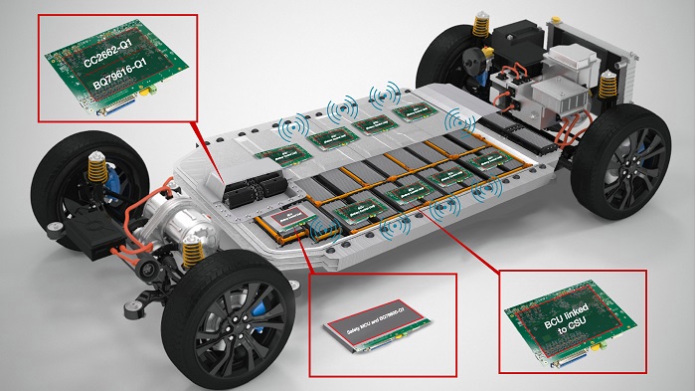

Using a new wireless protocol, developed specifically for the wireless BMS use case, TI’s wireless BMS functional safety concept addresses communication error detection and security. The proprietary protocol via the CC2662R-Q1 wireless MCU enables a robust and scalable data exchange between a host system processor and the newly announced BQ79616-Q1 battery monitor and balancer.

TI’s wireless protocol for BMS via the CC2662R-Q1 wireless MCU offers the industry’s highest network availability of greater than 99.999% and a network restart of 300-ms maximum availability. With this wireless MCU, dedicated time slots that provide high throughput and low latency protect data from loss or corruption while enabling multiple battery cells to send voltage and temperature data to the main MCU with ±2-mV accuracy and a network packet error rate of less than 10-7. Automakers can mitigate potential threats with security enablers from TI such as key exchange and refreshment; unique device authentication; debug security; software IP protection with a joint test action group (JTAG) lock; Advanced Encryption Standard (AES) 128-bit cryptographic acceleration and message integrity checks.

The deterministic protocol provides the highest throughput in the market, enabling automakers to create a battery module using a single wireless system-on-chip connected with multiple BQ79616-Q1 battery monitors for different configurations such as 32-, 48- and 60- cell systems. The system is designed to support up to 100 nodes with the industry’s lowest latency of less than 2 ms per node and time-synchronized measurements across every node. The CC2662R- Q1 wireless MCU isolates individual cell monitoring units, eliminating the need for and cost of daisy-chain isolation components. The BQ79616-Q1 battery monitor and balancer offers different channel options in the same package type, providing pin-to-pin compatibility and supporting reuse of the established software and hardware across any platform.

Automakers can jump-start their designs by downloading the SimpleLink wireless BMS software development kit (SDK), available at no cost and purchasing the SimpleLink wireless BMS evaluation module (CC2662RQ1-EVM-WBMS), which is available on TI.com for US$999. The CC2662R-Q1 wireless MCU is priced at US$2.79 in 1,000-unit quantities. The 16-channel BQ79616-Q1 comes in a 10-mm-by-10-mm, 64-pin thermally enhanced thin quad flat package (HTQFP), and is priced at US$6.90 in 1,000-unit quantities. All products featured in the wireless BMS solution are immediately available for purchase on TI.com.