In part 1, we provided an overview of the product life cycle (PLC) and product development cycle (PDC), noting their distinct differences. In this second part, we will explain in detail the 12 steps of the product development cycle (PDC).

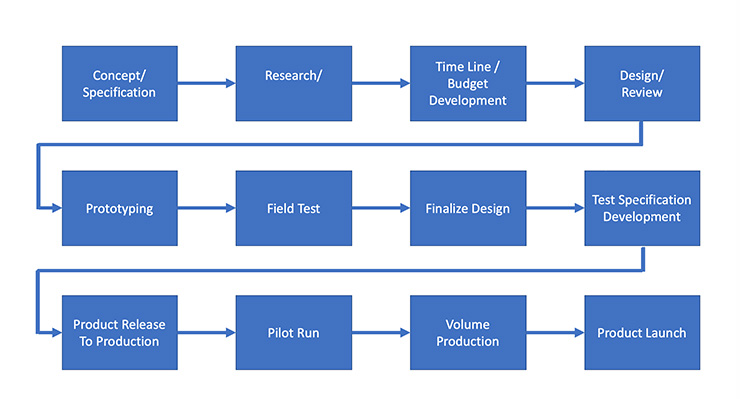

Figure 1 shows the typical flow chart of a PDC management process and the 12 steps it includes. Using a PDC is important because having a working process in place increases efficiency and the probability of product success.

- Concept/ Specification

- Research

- Timeline/ budget development

- Engineering development

- Design review

- Prototyping/test (Alpha test)

- Test specification development and certification

- Field test (Beta test) with customer feedback

- Product release to production

- Pilot run

- Final and volume production

- Product launch and introduction

PDC management process described

Concept/ specification

Product concepts and ideas can come from many sources including key customers, internal marketing and/or engineering departments. Sometimes it may be an idea suggested by a member of another department entirely different from marketing, such as production.

Initial market research

Depending on the size of the firm, this function may be conducted by marketing, a new product planning team or the management team. This covers many tasks from competitive analysis to customer contact to product idea validation to price comparison and product technology definition including MCU selection. It’s important for smaller companies and start-ups to carry out initial market research in order to avoid wrong investment decisions down the line. Having done the appropriate market research, the company will be able to develop products the market wants

Timeline/ budget development

Budget and timeline development can be a dynamic process for some and a formal process for others. It can be as simple as a few spreadsheet calculations or as complicated as using enterprise resource planning (ERP) software. The key is to be able to at least calculate the project cost, project average sales price (ASP) and sales volume. Calculating those can give the business unit manager (BUM) or product line manager (PLM) responsible for the profit and loss (P&L) of the product a clear picture of how much investment is needed. The budget and timeline development process also provides the break-even point and the return on investment (ROI) of the product based on the time schedule and resource requirements. Some refer to this phase as the feasibility study. After all the calculations are done, the BUM or PLM and sometimes corporate management, whose involvement depends on the size of the project, make a GO/NO GO decision.

Engineering development

Once the project is approved and funded, the engineering or development team will start the development work. It is strongly recommended that the development team participate in the above steps. At this point, the development team will start the design by defining the overall architecture, including the selection of microcontrollers (MCUs) and software operating systems (OSs). Fortunately, most MCU suppliers provide design reference kits and support to make development work easier. (Figure 2).

Figure 2: An example of a development system – The STM32 Nucleo from STMicroelectronics includes the adapter board containing the BlueNRG Tile, a coin-sized full-featured, ultra-low-power sensor node with onboard Bluetooth LE, an accelerometer and gyroscope, a magnetometer, pressure, humidity, and temperature sensors, a microphone, and a FlightSense Time-of-Flight sensor.

Design review

This is an important step and can generate conflict and friction between teams if not managed properly. Usually, the review team consists of members from marketing, engineering, and at times, the test team, production, and finance. When things don’t go well, for example, if the project incurs delays, it is very easy for the team members to blame each other. Additionally, it may take many review cycles before the product is done.

Prototyping/test (Alpha test)

To speed up the development cycle, developers often use development kits provided by the MCU vendors to do a proof of concept and beta tests. This approach will cut down the initial development time. When the first few product prototypes are produced, the development and test teams will go through an internal test, the alpha test. If problems are found, the developers will next use a troubleshooting process to fix the problems before launching field tests.

Test specification development and certification

This step usually goes in parallel with steps c, d, and e. While the product is being defined, the test team, whether it is one individual or a multi-member team, must start working on how to test the product, so it will not delay the development process. Often, the test team will provide helpful feedback to the development team to create products with easy access test points, helping to streamline the development process. Most products nowadays require some standard compliance. Test teams can help with the process. How does quality control fit in? Some organizations define quality control as an independent department, while others assign it to corporate management. Some believe quality is the responsibility of everyone and not just one department. Usually, it is an inspection and test function under production. The purpose of having quality control as a separate department or a corporate function is to avoid production shipping defective products.

Field test (Beta test) with customer feedback

When a product has successfully passed the internal tests, it is ready for the beta test. A beta test refers to taking the new product, not yet released to the public, to a few customers, who try it out and give feedback on what needs to be improved. It is important to provide this feedback to the development team, so they don’t develop products in a vacuum.

Product release to production

After a new product passes all the tests and has met the requirements of the product definition, the product is ready to be released to production. Representatives from each involved department will have a chance to review and approve the product release. There should be a formal sign-off procedure on record so that everyone will stand behind the product.

Pilot run

At this point, the production team will officially take over ownership of the product. Initially, depending on the product type, a small pilot run, on the order of 50 or so units, will go through the automated assembly line to see if the new products will work.

Final and volume production

After the initial pilot production run can produce close to 100% yield, with final sign-off from the production team representative (usually the production manager) the product is ready to be introduced.

Product launch and introduction

At this stage, the marketing or merchandising team will usually take over. The marketing team would have been working behind the scenes to get ready to introduce the product to the market. Some of these tasks (outside the scope of this article) include pricing, promotional plan, product brochure design, sales force and distribution channel training, stock and inventory forecast, etc. Two types of organizational plans have been used to manage products. In the first type, one marketing team will manage the product definition and introduction. The second type separates tasks, assigning the new product planning team to focus on product definition and the marketing or merchandising team to concentrate on promotion and sales.

In short, the twelve steps process described above provides a guideline for developers to map out a practical development plan to follow. In part 3, we will provide practical suggestions to implement the PDC.

Leave a Reply

You must be logged in to post a comment.