The automotive power window has evolved from a basic on/off switch and motor to a sophisticated motion-control subsystem with dedicated ICs.

In just a few decades, we’ve come a very long way from those bygone days of manually operated car windows, outside mirrors, and door locks. Now they are all electrically powered, with no manual backup linkage. Managing and delivering controlled power for the various motors and mechanisms used for the complicated door system and adjuncts — and it is truly a system — is a substantial design challenge.

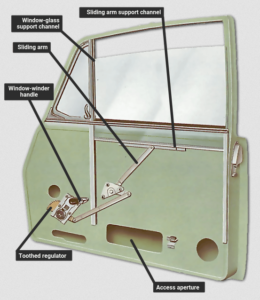

A look at car windows shows the change and how it has evolved. About 50 years ago, all car windows were manually operated via a mechanical linkage actuated by a simple “hand-powered” rotary crank, formally called the “window winder” by designers. Each occupant of the car had to manage his or her own window using their arm as the power source (Figure 1); the car’s driver could only do the adjacent window rather than all four.

You could buy a plain replacement crank (window winder) at any auto-supply store in case yours broke, and decorative aftermarket cranks were also popular (Figure 2).

Power windows were first introduced in the 1940s and initially used an electrically controlled, hydraulic-powered system since small electric-motor technology (size, power, and control) was not advanced enough to allow motors to be embedded into the door. The mechanism that moved the window up and down is called the window regulator.

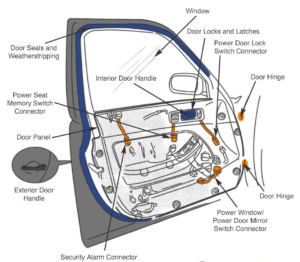

In the 1960s, the Cadillac Fleetwood came standard with windows powered solely by electric motors. Within about a decade, power windows were a standard feature on most cars, which is a fairly quick rate of mass-market adoption. By the start of the 21st century, the car door was transformed into a complex electromechanical subsystem with all functions activated electronically and implemented electrically without mechanical backup systems (Figure 3) (there was an intermediate period when doors and windows had both electrical and mechanical control, to overcome customer hesitation and provide a comfort factor).

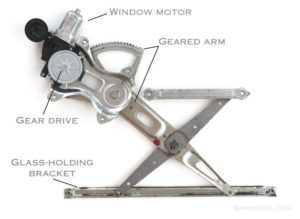

Two basic mechanisms were used for what is formally termed a window regulator: the Ford cable-type regulator (Figure 5), and the Toyota gear-drive-type window regulator (Figure 4).

Regardless of which mechanical design was used, both had one common electrical aspect. Unregulated 12-V DC power went directly from the car battery for the motor via the individual driver/passenger control switches of the respective window motors. As a result, incorporating this “convenience feature” into the car added to the ever-increasing burden of thicker cable harnesses and the challenges of routing them around the vehicle.

The next part looks at two application-specific ICs for automotive power windows and door functions.

WTWH Related Content

Understanding stop/start automobile-engine design, Part 1: The idea

Understanding stop/start automobile-engine design, Part 2: The starter motor

Understanding stop/start automobile-engine design, Part 3: The battery situation

Understanding stop/start automobile-engine design, Part 4: Mechanical wear issues

Understanding stop/start automobile-engine design, Part 5: Additional considerations

Understanding stop/start automobile-engine design, Part 6: Responses and work-arounds

Automobile Hands-Off Detection, Part 1: Basic issues

Automobile Hands-Off Detection, Part 2: Requirements

Automobile Hands-Off Detection, Part 3: Torque solutions

Automobile Hands-Off Detection, Part 4: Capacitive solutions

Electronic engines valves: an idea whose time has come … and gone?, Part 1: Conventional engine design

Electronic engines valves: an idea whose time has come … and gone?, Part 2: Improving the conventional design

Electronic engines valves: an idea whose time has come … and gone?, Part 3: The electronic camless approach

Electronic engines valves: an idea whose time has come…and gone?, Part 4: The camless outlook

External References

[1] GoMechanic, “Power Windows In Cars and the Interesting History Behind Them”

[2] Wikipedia, “Power Window”

[3] Samarins, “Power window regulator, window motor: problems, testing, replacement”