The programmable logic control (PLC) is the controller for many industrial processes; it is tightly focused and optimized for the task due to its rugged electrical, software, mechanical, and thermal design.

Part 1 of this FAQ looked at the basics of the PLC, its attributes, and virtues. Part 2 looks at how the PLC has changed from its inception, the present market, and the history of the PLC.

Q: Programmable products and their applications have changed dramatically in the past decades, along with expectations. How has the PLC changed?

A: First, PLCs support industrial network such as RS-485, Profibus, Modbus, USB, and even Ethernet, so connectivity is not an issue as it was in the early when they were mostly standalone systems).

Second, they now support many more I/O points and types. For example, they easily handle analog signals such as temperature, flow, and pressure, and analog outputs such as proportional valves, whereas the first PLCs handled only digital signals (on/off) and could only provide digital outputs.

Q: What about processing?

A: PLCs do not need the high-performance computational power of advanced PCs, nor do they need gaming-class graphics processors. But they are now expected to implement more sophisticated algorithms as part of the process-control function, so they now have higher-performance processors or coprocessors. Newer PLCs can scan through a ladder of hundreds of rungs in under a msec.

Q: Are they still restricted to ladder-logic programming?

A: Not at all. PLCs are now available with various high-level languages. Not only does this speed the programming itself, but it also allows for transportability between PLCs made from different vendors. This is a major advantage, although users tend to stay with a vendor are already using. The International Electrotechnical Commission (IEC) has developed a set of standards for programmable control systems, adding to their utility and versatility.

Q: Who are the key vendors in the PLC market?

A: There are many, among them Honeywell International, Mitsubishi Electric Corporation, Schneider Electric, Omron Corporation, Rockwell Automation, Siemens AG, ABB Ltd. General Electric, Hitachi Industrial Equipment Systems Co., Ltd., and Allen Bradley.

Q: Still, it seems that PCs are a better choice than PLCs, as their high volumes lead to lower costs. Is that the case?

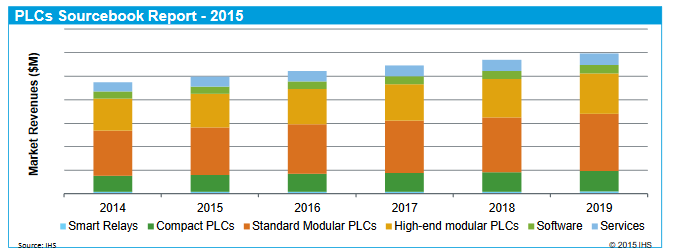

A: Again, the real-world virtues of the PLC, in terms of hardware ruggedness, analog and digital I/O capability and compatibility, software integrity, packaging, and more, still makes the PLC the unit of choice for many industrial situations. There are many market studies available; this one from IHS Technology says that it is a solid growth market, Figure 1.

Fig 1: This graph shows the recent and near-future projected market for various aspects of the PLC market. (Image source: IHS Technology)

Q: How is the market for PLCs divided?

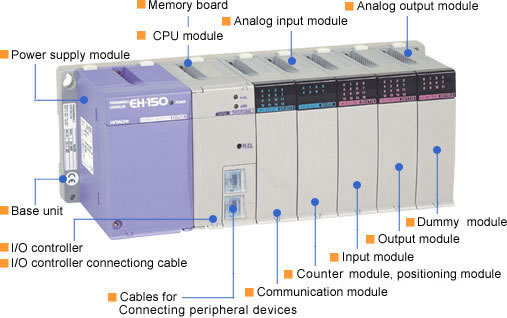

A: There are two basic PLC groupings: embedded and modular. Embedded PLCs are dedicated, relatively closed, standalone units which cannot be expanded (or can be, but only a little) and are well-suited for well-defined tasks with known I/O needs and with a limit on their needed functionality. Modular PLCs are often rack-mounted and can be expanded by adding new modules to the bus or chassis, Figure 2. These modules add more and different types of I/O, and even add additional computation power if desired.

Fig 2: The PLC has come a very long way in form, function, and capabilities over nearly five decades, as the detailed image of this new one clearly shows. (Image source: Tech Zephyr)

Q: How are the PLC sizes designated?

A: There is no formal industry standard, but the general groupings are nano, micro, mini, standard, and modular, primarily determined by the number of I/O points the PLC can handle. A nano unit might have only up to 16 I/O points, a micro PLC might have up to 520 I/O including over 100 analog ones, and a high-end modular unit can support thousands of points. In recent years, the capabilities and connectivity of the smaller units have increased to such a level that many large installations, are tending towards increased use of the smaller units for highly localized, immediate control, and then networking these for a larger system umbrella.

Q: What’s the history of the PLC?

A: In brief: in the 1960s, General Motors Hydramatic (the automatic transmission division of General Motors) decided that an electronic verso of the relay-based system might offer significant benefits to the production lines and efficiency. Theyissue a request for proposals (RFP) for a unit which had to meet goals of physical ruggedness, compatibility with existing ladder logic, and deterministic behavior. Four companies responded: Bedford Associates headed by Dick Morley (a self-schooled MIT dropout); Digital Equipment Corp (DEC), with a minicomputer-based solution; Allen-Bradley with a credible but large and complex unit; and Century Detroit. The proposal by Morley and his team, Figure 3, was the only one accepted, and they formed Modicon, a contraction of MOdular Digital.

Fig 3: The Modicon development team and the 084, left to right: Dick Morley, Tom Boissevain, the Modicon 084, George Schwenk, and Jonas Landau. (Image source: Automation.com)

Q: End of story?

A: Of course not! The Model 084 was delivered in 1969; in it were a processor board, memory, and a “logic solver” board, which parsed the algorithms associated with ladder logic. The Modicon 084 was not a success, as it was slow, somewhat cumbersome, had “architectural” issues, and lacked some useful features. Yet it provided enough advantages that the Modicon team was asked to continue the work. In 1973, they introduced the Modicon 184, which is recognized as being the first mass-market PLC to achieve success, Figure 4.

Fig 4: The Modicon 184 was the PLC that ignited the market and began the changeover from relay-based control to solid-state units. (Image source: AutomationDirect.com)

Modicon was purchased in 1977 by Gould Electronics, later acquired by German’s AEG, and then by French supplier Schneider Electric, the current owner. Dick Morley was a fascinating person both professionally and personally (see References); he passed away in October 2017.

Q; Who supports the PLC market?

The PLC market is very attractive and vendors of signal-conditioning IC, who are constantly introducing new components which increase the types of signals handled, the I/O density, speed, and other attributes. Similarly, vendors of rugged, high-reliability power supplies are introducing smaller, more efficient, lower-dissipation units to serve this market.

PLCs are not “junior” or limited PCs; instead, they are application-focused systems with significant analog and digital I/O plus rugged circuitry, software, and packaging design, all optimized for their task without extraneous features or functions.

References

- History of the PLC

- The Evolutionary PLC: Past, Present, and Future

- History of Control–History of PLC and DCS

- The concise PLC History

- PLC Timeline

- Programmable logic controller

- The Father of Invention: Dick Morley looks back on the 40th anniversary of the PLC

- Remembering a Manufacturing Legend, Dick Morley

- Control Station, “Dick Morley and the Story of the PLC”

- Control Engineering, “Dick Morley remembered as ‘Father of the PLC’ “

- Allied Market Research, “Programmable Logic Controller (PLC) Market – Global Opportunity Analysis and Industry Forecast, 2017-2023”

- Global Market Insights, “Programmable Logic Controller (PLC) Market Size, Industry Analysis Report”

- Markets and Markets, “Micro and Nano PLC Market”

Leave a Reply

You must be logged in to post a comment.