MegaChips today introduced the eDSP™, a low-power, high-performance sensor processing platform that performs high-end arithmetic processing in real time at a fraction of the power compared to the microcontroller-based solutions on the market today. It meets customer needs for the highest flexibility in hardware design with right-sized horsepower to run their most computationally challenging algorithms at high speeds with the lowest power available today.

MegaChips today introduced the eDSP™, a low-power, high-performance sensor processing platform that performs high-end arithmetic processing in real time at a fraction of the power compared to the microcontroller-based solutions on the market today. It meets customer needs for the highest flexibility in hardware design with right-sized horsepower to run their most computationally challenging algorithms at high speeds with the lowest power available today.

In mainstream market reports, the explosive growth of the IoT is most often discussed in terms of consumer devices and products. But when considering the scale of the non-consumer products sector, it is set to dwarf the size of the consumer IoT by several magnitudes. While a few billion consumer devices— wearable, home automation appliances, cars—are forecasted during the next five years, the equivalent global growth curve for the non-consumer IoT is set to rocket towards 100 billion devices as the technology becomes pervasive in the non-consumer sectors worldwide. As the sensor fusion market and applications are extending outside of the consumer markets into more specialized high-end applications such as healthcare, industrial, transportation, agricultural and others, a new design approach is required.

“Today’s out-of-the-box solutions are mainly designed for consumer applications and lack the flexibility or the performance required by system engineers for their high-end specialized applications,” said Michael Navid, VP of Business Development and Marketing at MegaChips. “They find themselves cornered into choosing among the less attractive, power hungry microcontroller-based designs, or the less flexible, off-the-shelf integrated sensor fusion solutions. When it comes to sensor fusion, there is no one size fits all, so we provide developers with an alternative platform through our eDSP product family with the flexibility to choose from a wide variety of external sensors and the freedom to implement their own differentiated fusion algorithms using our comprehensive development tool chain and reference design packages, reducing their time to market and cost.”

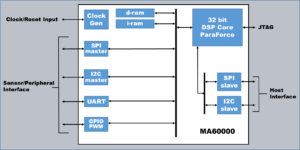

eDSP integrates a 32-bit programmable DSP core, 256K RAM for instruction, 256K RAM for data and a multitude of interfaces. MegaChips’ eDSP delivers four times higher performance with 98% less power than the ARM Cortex-M4F, and can execute 2.5 times faster than the Cortex M4 based designs complex mathematical algorithms such as Kalman filters, Matrix, and FFT calculations, typical benchmarks for the sensor fusion space, while providing a higher level of programmability and customization.

The DSP core includes a 3-way VLIW (Very Long Instruction Word) and a 4-way floating point SIMD (Single Instruction Multiple Data), which makes it extremely effective to exploit the intrinsic parallelism of most sensor fusion challenges. Furthermore, it performs multi-way branching and conditional execution allowing programmers a fine grain control on concurrent instructions execution. These unique features provide higher performance and lower power without the complexity inherent to other microprocessor-based designs.

The eDSP evaluation kit provides system engineers with all the required hardware, software and documentation to quickly set up and use the platform. The eDSP software development tools include a comprehensive collection of code generation and analysis tools that speed the application software development process. The Eclipse-based Integrated Development Environment (IDE) provides a very familiar platform experience for any embedded software engineering professional.

eDSP is available now in a compact 3.5mm X 3.5mm FBGA-49 package with an operating temperature range of -40° to +85°C.

The post Sensor processing DSP handles high-end apps appeared first on Microcontroller Tips.