By Ed Cady, contributing editor

It is amazing that after five decades of copper twin-axial raw cable developments, shipments and diverse applications, there are several newly released raw cable products being used for several new generation I/O interface standard and custom cable assemblies. These cables are being used for both internal and external assemblies applications used within new consumer, enterprise infrastructure, commercial datacenter and very high-performance computing systems.

There are still challenges and issues for the manufacturers and users of these new products; for example, budgeting for very expensive test equipment for 56 Gbps per lane circuits and designing in the capability of handling 100-W power closely adjacent to sensitive high-speed digital signaling per interface specs like USB3.1 and the latest Power over Ethernet IEEE-802.3 specifications.

Here are some suggestions a cable assembly developer might consider as part of the component engineering process.

- Pick strong suppliers that can address any and all material, process, quality, performance and testing variations details. I/O Link assemblies should use raw cable from one reel because of slight but critical performance variations from one reel and to another. It’s all related to how tight the cable is reeled up and the difficulty of maintaining structure symmetry. Usually each reel of raw cable is individually measured, characterized and documented for use by the cable assembly supplier and traceability by the OEM or end-user.

-

Look for very pure copper conductor elements with very low oxygen content for optimized conductivity. Take note of conductor silver-plating smoothness and purity. This enables best electrical skin effect relative to signal launch path, insertion loss, jitter and reflection loss.

- Ascertain tradeoffs and best criteria when selecting wire conductor gauge size versus electrical signaling reach. Look closely at dielectric material properties that will achieve needed signaling performance ranges. This may include evaluating air, solid and foam types. Look for process variation tolerance and control of bubble size, symmetry, density and distribution.

- Twin-axial differential pair elements need to be layered within the bundle for optimized element fan out and prepping relative to termination zone. The pair shields, whether solid or wrapped, need to hold tight geometries when processing and wire termination prepping. The same is true for cable bundle shields and fillers. Bundle diameters and bend radius need to be designed relative to cable routing.

- Be aware of the latest cable jacket regulatory testing and material constraints required by UL, Telcordia, TUV, NEC, IEC and ISO per application. Some customers require inline testing and histograms for raw cable and cable assemblies.

-

The most critical area to manage is wire termination to contacts or PCB pads for both signal and ground conductors and cable bundle shield termination. Learn and apply the best technologies for wire termination shaping, smoothness, welding or soldering processing.

Some new cable product offerings with positive market feedback include:

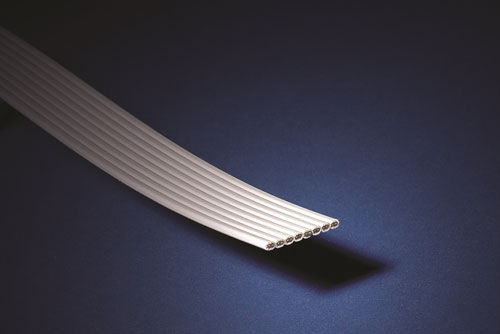

- TE’s new Silver internal flat twin-axial cable for cabled backplanes

- Lorom’s new 56 Gbps twin-axial cable for external and internal IO assemblies

- 3M’s internal flat-foiled micro-twin-axial cable for cabled backplanes

- Wireworld’s new Starlight Cat 8 ribbon twin-axial cable with Tite-Shield 3 layer shield for infrastructure applications

Some other top raw cable suppliers with excellent product to keep track of are Hitachi Manchester, Molex TempFlex, Leoni, Prysmian and Microcoax Inc.

The post How do you specify twin-axial, high-speed I/O cabling? appeared first on Wire and Cable Tips.