Despite some initial difficulties, it is reasonable to think that OLED (organic light emitting diode) displays will replace LCDs, making possible low-power flexible screens relatively inexpensive to manufacture. OLEDs have several advantages. For one thing, they can be made onto a suitable substrate by means of silk screen-printing or an inkjet printer. Roll-to-roll vapor deposition methods permit economical mass production of OLEDs. The downside for now is that multi-layer devices have registration problems, i.e. lining up printed layers to the required degree of accuracy.

OLEDs lend themselves to production on flexible plastic substrates, facilitating development of new applications such as roll-up displays embedded in fabric or built into curved walls. Compared to LCDs, OLEDs exhibit a superior contrast ratio and wider viewing angle because the pixels emit light directly. The black level is deeper because a black OLED emits no light. (LCDs filter the light from dark areas, so there is no absolute black, except in recent models, which turn off the LED backlighting to create a perfectly black screen.) An inactive OLED element does not consume power. And OLEDs render superior video because they have a faster response time compared to LCDs.

Currently there remain some disadvantages when it comes to TV displays, including above all limited lifetime. A typical OLED TV panel after 1,000 hours experiences a 12% blue luminance degradation with 7% red and 8% green reduction. In comparison, LCDs have 25,000 to 40,000 hour ratings to half brightness. (A point to note: TVs advertised as LED TVs–not OLED TVs–actually have LCD technology. The LEDs provide backlighting instead of traditional cold-cathode fluorescent backlights. LED-backlit displays use the same TFT LCD technologies as CCFL-backlit LCDs.)

An OLED generates light via a mechanism that differs from that of ordinary LEDs. Ordinary LEDs are comprised of a semiconductor material, usually a GaN compound, that releases energy in the form of photons when electrons in the semiconductor recombine with electron holes. The color of the LED light (corresponding to the energy of the photons) is determined by the energy electrons need to cross the band gap of the semiconductor. A layer of light-emitting phosphor often sits on the LED semiconductor to produce white light.

An OLED generates light via a mechanism that differs from that of ordinary LEDs. Ordinary LEDs are comprised of a semiconductor material, usually a GaN compound, that releases energy in the form of photons when electrons in the semiconductor recombine with electron holes. The color of the LED light (corresponding to the energy of the photons) is determined by the energy electrons need to cross the band gap of the semiconductor. A layer of light-emitting phosphor often sits on the LED semiconductor to produce white light.

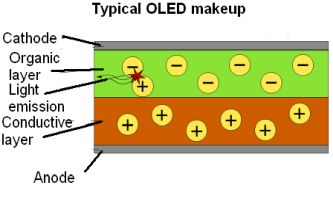

In contrast, OLEDs contain organic material between their anode and cathode. For OLEDs on plastic substrates, the organic material is a version of the polymer poly(p-phenylene vinylene). The highest occupied and lowest unoccupied molecular orbitals (HOMO and LUMO) of organic semiconductors are analogous to the valence and conduction bands of ordinary semiconductors. In addition, OLEDs often contain a special conductive layer of material chosen to aid charge injection at electrodes. This material is typically PEDOT:PSS, used because its HOMO level generally lies between the work function of ITO, which typically serves as the OLED’s transparent anode, and the HOMO of other commonly used polymers, reducing the energy barriers for hole injection. Metals such as barium and calcium are often used for the OLED cathode as they have low work functions which promote injection of electrons into the LUMO of the organic material.

Electrical current flows through an OLED from cathode to anode, as electrons are injected into the LUMO of the organic layer at the cathode and withdrawn from the HOMO at the anode. The withdrawal of electrons at the anode may also be described as the injection of electron holes into the HOMO. Electrostatic forces bring the electrons and the holes toward each other. They recombine to form an exciton, a bound state of the electron and hole. The decay of this excited state results in a relaxation of the energy levels of the electron, accompanied by emission of radiation having a frequency in the visible light region. The frequency of this radiation depends on the band gap of the organic material, in this case the difference in energy between the HOMO and LUMO.

There are two types of OLED display modules. They are differentiated by how the OLED display is powered. PMOLED, for Passive-Matrix OLED, uses a simple control scheme in which each row (or line) in the display is sequentially lit (one at a time). PMOLED electronics do not contain a storage capacitor and so the pixels in each line are actually off most of the time. To compensate, the display power supply produces a voltage high enough to make the OLED pixels brighter.

PMOLEDs are inexpensive and also restricted in resolution and size (the more lines in the display, the more voltage necessary). PMOLED displays are usually small (up to 3 in typically) and are used to display characters or small icons. They typically are found in wearable devices and small appliances like hand tools.

The AMOLED (or Active-Matrix OLED) display consists of a matrix of OLED pixels deposited or integrated onto a thin-film transistor (TFT) array. The TFTs generate light upon electrical activation and function as a series of switches to control the current flowing to each individual pixel. Typically, this continuous current flow is controlled by at least two TFTs on each pixel, one to start and stop the charging of a storage capacitor and the second to provide a voltage source at the level needed to create a constant current to the pixel and eliminate the need for the high currents as necessary for PMOLEDs. AMOLED displays consume the zero power with a black screen and the most power with a white screen. Thus AMOLEDs consume less power than PMOLEDs, have faster refresh rates and make possible larger displays with higher resolutions. Smartphones, digital cameras, and OLED TVs are all AMOLED devices.

Both types of OLED displays require a relatively high voltage (usually around 12 V) but a relatively small current (usually less than 100 mA).

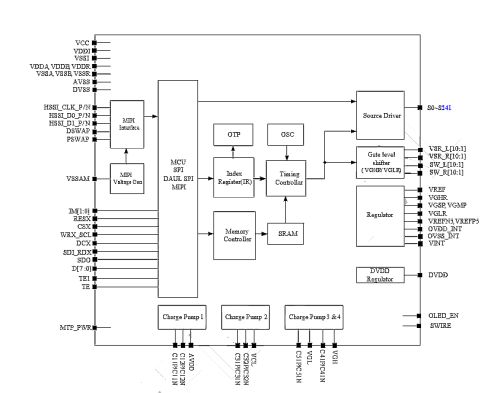

When it comes to using OLED displays, the electrical interface of an OLED display module is generally a lot like the interface for an LCD or LED matrix. Display modules using all these technologies typically either accept conventional digital inputs or incorporate widely used serial interfaces such as I2C. More sophisticated OLEDs generally use a DSI serial interface