Bluetooth-enabled tire monitors will check inflation pressures and temperatures with much more precision than available through yellow lights on a dash panel.

Addy Mulders, Dialog Semiconductor

The words “connected cars” often bring to mind self-driving autonomous vehicles. But connected cars will offer a variety of capabilities, not the least of which is tire pressure monitoring systems (TPMS).

The words “connected cars” often bring to mind self-driving autonomous vehicles. But connected cars will offer a variety of capabilities, not the least of which is tire pressure monitoring systems (TPMS).

As its name suggests, TPMS provides real-time data on vehicle tire pressure, so no one need be surprised by a flat tire. Beyond that, though, TPMS also offers critical information on tire temperature -– temperatures that are too high can indicate an excess of friction caused by misalignment of the wheels, which contributes to early tire wear and less safe driving. Newer, tire-mounted models are able to also gauge acceleration and, in some cases, the direction of wheel spin. Additionally, TPMS sensors provide insight into their own battery voltage levels, indicating when they should be replaced.

TPMS can only do so much on its, own, though. And, for all the benefits this system provides, its capabilities and applications for the connected car are greatly expanded when integrated with Bluetooth low energy (BLE) connectivity.

Basics of TPMS

TPMS became mandatory in the U.S. and EU in 2007 and 2014 respectively. There are two types of TPMS, direct (dTPMS) and indirect (iTPMS). Indirect TPMS do not use physical pressure sensors. Instead, they monitor air pressure primarily by measuring the rotational speeds of individual wheels. This works because under-inflated tires have a slightly smaller diameter (and hence higher angular velocity) than those correctly inflated. These differences are measurable through the wheel speed sensors of ABS/ESC systems.

A main difficulty of iTPMS is that it cannot measure absolute pressure values. When the tires are inflated to the correct pressure, the press of a reset button calibrates all ensuing measurements relative to these initial readings. Also, iTPMS are sensitive to the influences of different tire styles, road surfaces, and driving speeds.

In contrast to iTPMS, direct TPMS reports absolute tire pressures. It does so through use of pressure sensors typically located on the inside of each tire rim. Some units also measure and report tire temperatures. Many TPMS display real-time tire pressures both when the vehicle is moving and when parked.

Most dTPMS are battery powered. Some sensors employ a wireless power system, based on electromagnetic induction, resembling that used in RFID tag reading. This makes the sensor more lightweight.

The batteries powering dTPMS aren’t replaceable – when the battery runs down, the whole sensor is replaced. Also, sensitive electronics within the dTPMS wear out with time and can be influenced by pressure and vibration. TPMS sensors in low-profile wheels also tend to wear out more quickly, especially if they experience poor road conditions.

Today, TPMS most commonly uses 315 MHz in the U.S. for transmitting tire information to the receiver in the vehicle. But the frequency used varies from region to region, so there is no single worldwide platform to support it. In rolling mode, sensors transmit on average about every 60 to 180 seconds. While parked or in stationary mode, depending on the manufacturer, sensors may transmit periodically or when sensors detect a pressure change. In the event of rapid air loss, most sensors go into an alert mode that transmits a warning.

Unfortunately, direct TPMS radio signal technology is prone to interference. Most TPMS sensors are activated with a low-frequency signal at 125 kHz. Reception of this LF signal forces the sensor to transmit. Several widely used pieces of test equipment found in auto shops emit signals near these frequencies. Signals coming from other autos sometimes can also actuate transmission as well.

Such difficulties have led several manufacturers to base TPMS on Bluetooth Low Energy (BLE) communication standards. BLE both provides a single worldwide platform – cutting down on development, qualification and logistical costs – while allowing over-the-air firmware updates and other general maintenance that would otherwise not be possible. In short, BLE ensures that TPMS sensors are constantly kept up-to-date, secured, and optimized.

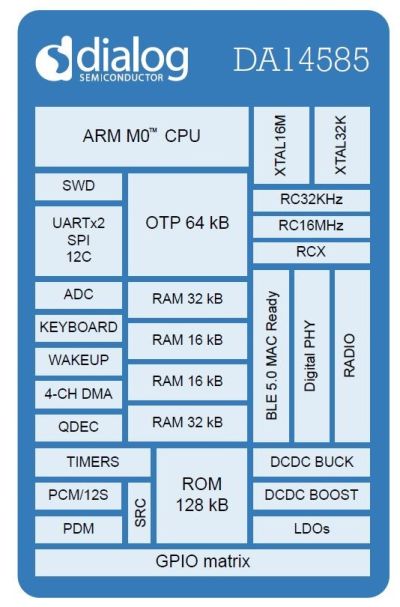

he DA14585 is the smallest, lowest power and most integrated Bluetooth SoC. It can serve as a means of adding Bluetooth low energy not only to TPMS, but also to products like remote controls, proximity tags, beacons, connected medical devices and smart home nodes. It supports all Bluetooth developments up to and including Bluetooth 5 and Bluetooth low energy Mesh.

Additionally, BLE offers more data bandwidth that opens the door for new potential use cases. For example, it may facilitate the outfitting of other sensors throughout the vehicle, such as tire deformation sensors that can more closely monitor the condition of the tires.

Current OEM TPMS chips only offer connections to the car body electronics and will flash dashboard warnings to the driver when tire pressure readings drop to concerning levels. But a BLE-enabled TPMS sensor can connect directly to the driver’s smartphone for a more direct line of communication. This feature may be redundant for drivers whose dashboards already display TPMS warnings, but it can be helpful for drivers whose dashboards lack this warning.

The transportation sector, in particular, can benefit from BLE-enabled TPMS. Transportation companies optimize their vehicles’ tire pressure to minimize tire wear and fuel consumption. Eighteen-wheelers must connect to various trailers built by equally various manufacturers. A standard TPMS retrofit system that spans the dashboards of all trucks and trailers is still a long way off, but a TPMS that connects directly to the driver’s phone or tablet helps to fill that niche.

BLE-enabled TPMS can do much more than just monitoring tire wear and pressure. For example, consider capabilities enabled by use of the SmartBond DA14585, the smallest, lowest-power, and most integrated Bluetooth 5 SoC. The chip’s BLE connectivity provides a range of additional potential applications for TPMS, including keyless entry, onboard diagnostics (OBD) telematics and various sensor applications and remote-control functions.

TPMS sensors integrated with the SmartBond DA14585 and its BLE connectivity support can improve the tracking, monitoring, and maintenance of these vehicles. Moreover, they can do so in a way that lowers manufacturing costs and provides engineers with new avenues for smart automotive applications.

Leave a Reply

You must be logged in to post a comment.