Three elements are necessary to effectively implement energy harvesting (EH) into wireless IoT nodes, wearables and similar low-power applications. First, it a detailed power profile needs to be developed that considers active and sleep modes to produce a realistic estimate of the average power consumption. The power profile is used to size both the harvester and the energy storage elements. An energy storage element needs to be identified that can support the peak power needs and operating lifetime of the system.

The final element is designing the overall power architecture and identifying the specific power management IC that effectively manages the harvester and supports the power demands of the device including charging the energy storage element.

Power profiling

Development of a comprehensive power profile is foundational when designing a wireless IoT node or wearable powered by ambient energy. A power profile is developed through an analysis of the amount of average power consumed by every system component. The power profile needs to consider both average power requirements and peak power demands.

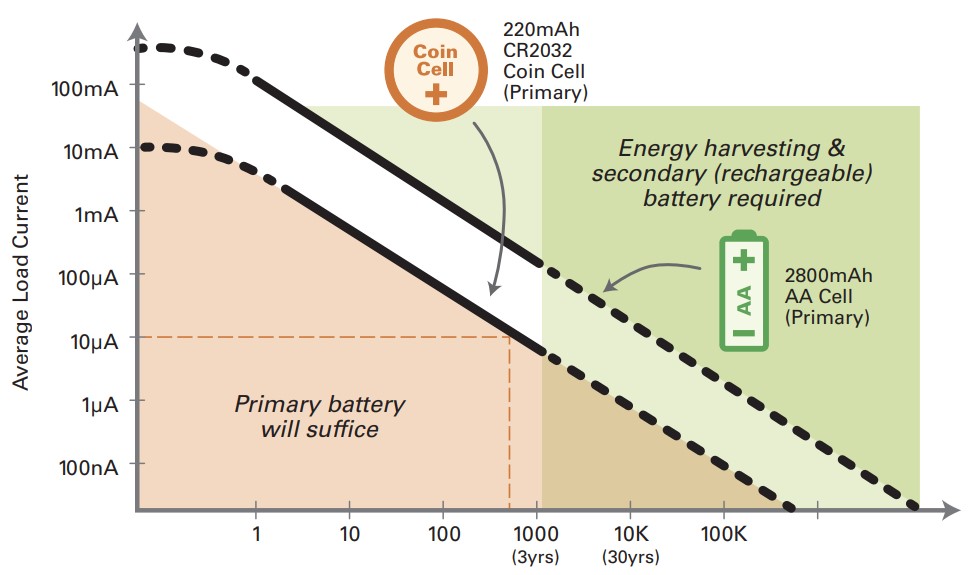

The average load current calculations (with appropriate derating) can be used to determine if the device can be powered with a primary battery or if a combination of energy harvesting and an energy storage device are required to ensure reliable operation over the design lifetime of the device.

The figure above can provide a quick framework for estimating whether a primary battery will suffice or if energy harvesting is needed to obtain the desired lifetime. The horizontal axis of this graph shows days of operation required for the device, while the vertical axis shows the average load current on a logarithmic scale.

This graph shows the estimated lifetimes for a 220mAh CR2032 coin cell and for a 2800mAh AA primary battery. The dotted lines in the lower-left part of the graph show that devices with an average current draw of 10µA can be expected to operate for 2 years powered by a 220mAh CR2032 coin cell primary battery.

If the IoT device being considered consumes less 10µA, a conventional battery will provide all of the required power. Most real-world designs require average currents of more than that, often 50µA and above, in those cases two design choices can be considered:

- Use a larger primary cell, an option that only works if enough space is available

- Combine an energy-harvesting device with a rechargeable battery

The power profile must also consider the operating characteristics of the device over time, not just the average power consumption. For example, many IoT wireless sensor nodes spend up to 90%+ of the time in sleep mode, drawing only quiescent current. For about 10% of the time, or less, they are waking up, poling the sensor, processing the sensor information, and transmitting the resulting data. During that short period, the power spikes and can be orders of magnitude higher than the average or quiescent currents. That means that the energy storage device must be able to support very high peak power draws over short periods.

Power architectures

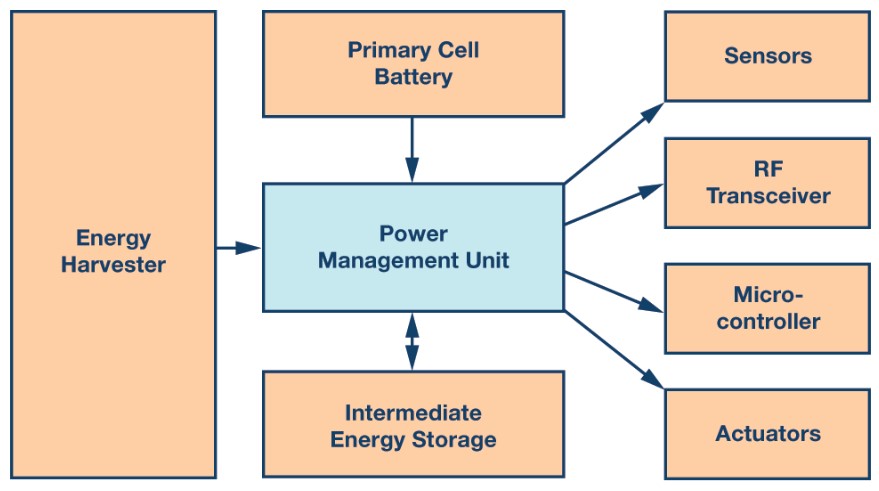

Once the average and peak power requirements have been determined, it’s possible to design the power management system for the device. The common elements in all EH-powered devices are the energy harvester, the power management unit and some form of energy storage. Choices of energy harvesters were reviewed in part two of this FAQ series, “Energy Harvesting for the IoT and Ambient Energy Availability.”

Not every system will have all of the elements illustrated above. In many designs, there is no primary cell battery, many devices lack actuators, and so on. And, there is a growing number of sensors, RF transceivers (or simply a transmitter in some designs), ultra-low power microcontrollers, and other components optimized for use in EH-powered devices. This section will provide a brief review of the power management and energy storage needs of these devices.

Selection of the power management unit must take into consideration the EH device being used (does it need maximum power point tracking to ensure optimal performance?), the type of energy storage device and its optimal charging profile, and it needs to be able to support the peak current demands of the system. A charge pump can be included to support low start-up voltages as the boost converter section ramps up. The ability to support multiple energy harvesting technologies such as both photovoltaic and piezoelectric or thermoelectric devices may be needed in certain design cases. Some power management units allow for designs that incorporate both rechargeable and primary batteries.

Selection of the energy storage element also needs to take into consideration numerous factors, some of which are detailed in the figure below:

This completes the three-part energy harvesting FAQ series. The first article in the series covered, “Energy Harvesting Applications, Architectures and the Massive IoT,” while the second article focused on, “Energy Harvesting for the IoT and Ambient Energy Availability.”

References:

Energy Harvesting Solution To Go, Wurth Electronics

Energy Harvesting for Low-Power Sensor Systems, Renesas Electronics

New Advances in Energy Harvesting Power Conversion, Analog Devices