Depending on how they are used, digital shadows take different forms and can be created using different techniques. Digital twins, on the other hand, have a specific definition within model-based systems engineering (MBSE): a virtual representation of a device or system that spans its life cycle, from initial conceptualization and specification through end of life, is updated in real-time to provide a common source of ‘truth’ for diverse design and manufacturing teams, and uses simulation, and increasingly, machine learning, to assist in decision making.

This FAQ begins by comparing and contrasting digital models, digital shadows, and digital twins looks at where ‘pre-digital-twins’ fit in, presents types of digital shadows, and compares how to cast a digital shadow versus scanning a digital shadow.

While digital models and digital twins are used throughout the system lifecycle, digital shadows are created for specific uses at various points in time. They are mostly used after the design is completed in Industry 4.0. Digital twins are used to model cyber-physical systems, and digital shadows are often used to model a system being built in a cyber-physical production system (CPPS) that operates within the industrial internet of things (IIoT). While there is a single digital twin, a CPPS can have multiple digital shadows with varying levels of detail at different points in time, describing a different aspect of the system.

In addition, digital twins are tightly correlated to digital threads, while digital shadows are not necessarily correlated with a digital thread. The digital thread is a continually updated history of a digital twin, with all changes, additions, and deletions maintained in real time. Digital shadows are collections of data traces put together for a specific purpose and can include measured parameters as well as historical information but do not necessarily have a complete historical record. And it may not be a ‘complete’ representation of the entire system. A digital shadow can include abstractions in place of detailed data to improve processing performance.

Data flow in models, shadows, and twins

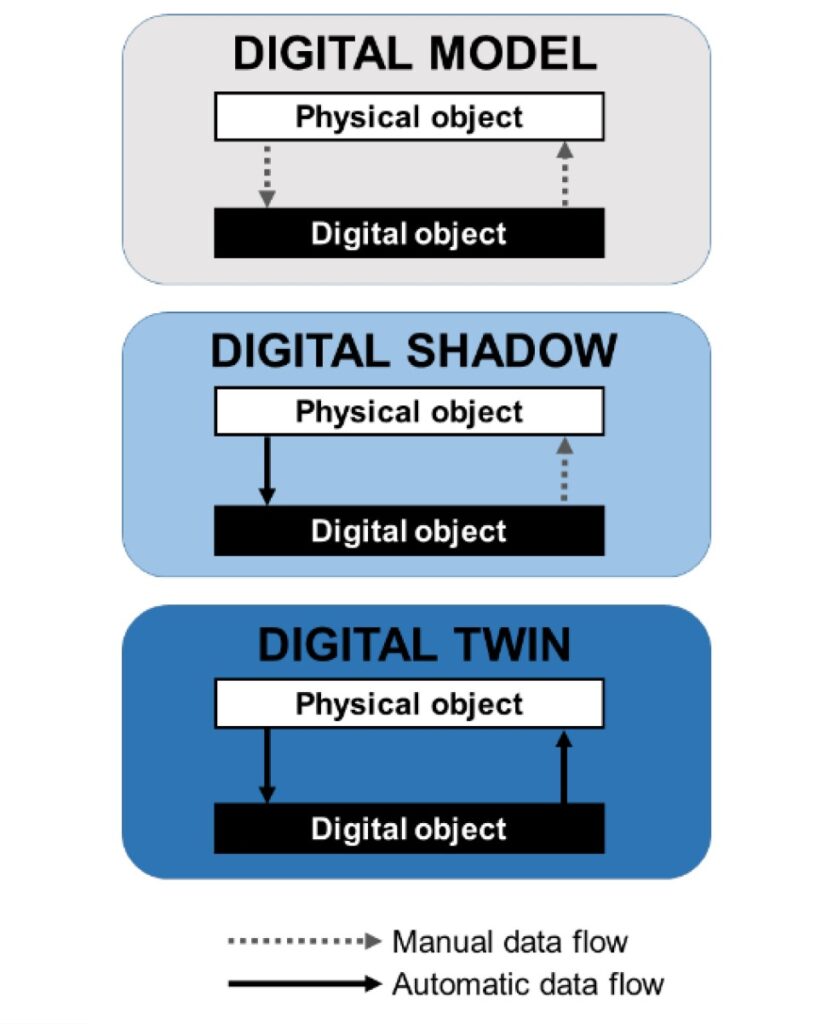

From the perspective of data flows, a digital shadow fits in between a digital model and a digital twin (Figure 1). A digital model does not include any automated data flows between the digital and physical worlds, is more or less static (unless manually updated), and exists in isolation. A digital twin has a tight connection between the digital and physical worlds with fully integrated data exchanges in both directions. A digital shadow lies in between with automated data flowing from the physical world to the shadow, but not from the shadow to the physical world.

What’s a pre-digital twin?

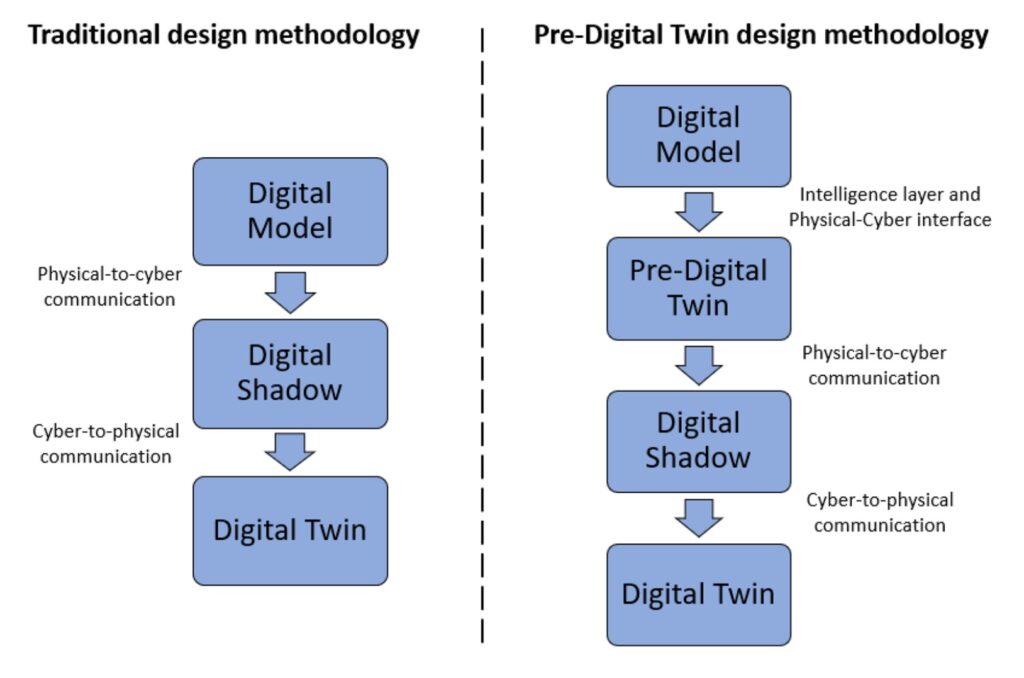

In addition to the digital model, digital shadow, and digital twin, some MBSE implementations include the concept of a ‘pre-digital twin’ and a slightly different definition of a digital shadow (Figure 2):

- The digital model is a basic copy of the physical object without any automated data exchange between the physical world and the model.

- The pre-digital twin is a more detailed virtual model of the system created before the fabrication of any physical representations or prototypes and is designed to provide early identification of technical defects and risks.

- The digital shadow adds one-way data flow from the object to the digital model and can enhance the digital model by synchronizing it with the real world.

- The digital twin is a complete virtual representation of the object or system. It is updated in real-time with data flowing from the system to the twin and from the twin to the system in the form of physical changes to advance the design process.

While there is only one digital twin that serves as the single source of ‘truth’ about the complete system for diverse engineering groups, a given CPPS can have many different digital shadows describing specific aspects of the system at different times, with varying sets of data, and in different levels of detail.

Digital shadow types

Digital shadows can be categorized based on their purpose or their relationship with the corresponding digital twin. When designed to serve a specific purpose, the digital shadow works in isolation from the digital twin, and the shadow type provides a blueprint of the data needed, the sources of the data, the relationships between various pieces of data, and any data manipulation to be performed by the shadow.

A second type of digital shadow is defined as interacting with the corresponding digital twin. In this case, the digital shadow is a sufficiently detailed data set of the production processes, system, and related development activities to support a real-time evaluation. The digital shadow directly forwards the data to the digital twin or performs some preprocessing and/or simulations. Based on the data delivered by the digital shadow, the digital twin can integrate it into the complete digital reality for detailed processing, simulation, and analysis.

In either case, digital shadows can add metadata about time, location, and even the weather conditions, apart from data derived directly from the system. Any metadata used must be included as part of the digital shadow type or definition. Digital shadows can be created using software or hardware tools. Most shadows are created using digital shadow casting software.

Casting a digital shadow

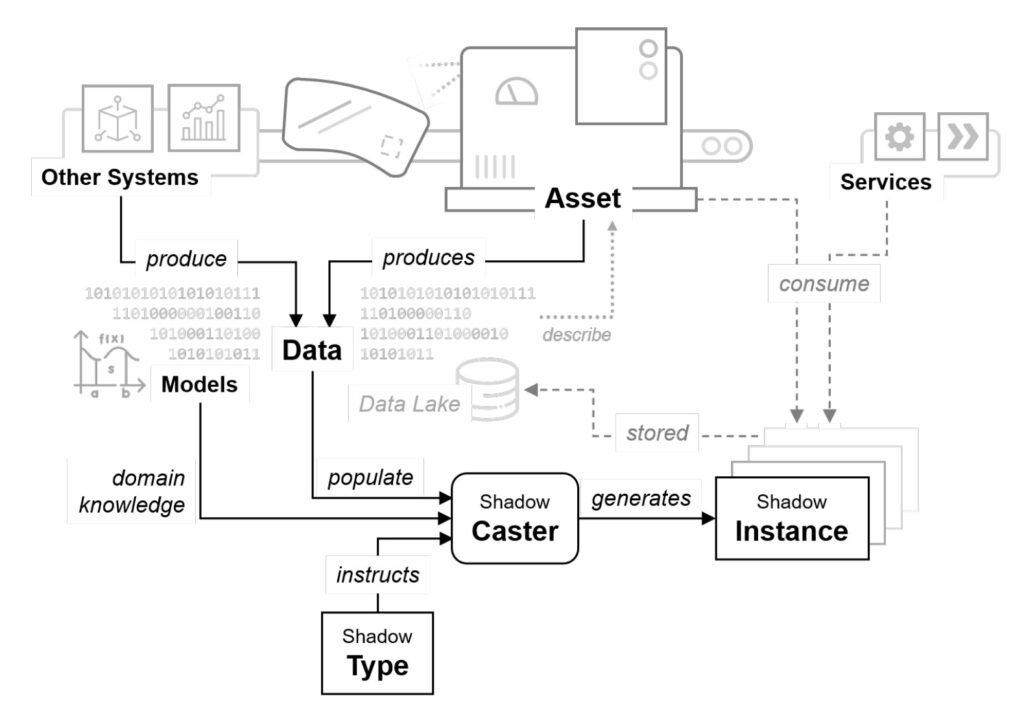

A digital shadow can be created using digital shadow caster software. The shadow caster uses the digital shadow type as the ‘blueprint’ to determine what data to gather, what models to consult, and how to combine them into a digital shadow instance (Figure 3). The digital shadow type can also contain information about the temporal existence of the shadow, including:

- A snapshot of a specific instance in time that produces a static shadow

- A continuously varying shadow that monitors the real-time state of an asset.

- A shadow that is triggered by specified conditions, such as shadows created at scheduled times or on specific time intervals, or event-driven shadows, such as when a data value exceeds a threshold level.

- Shadows can be created retrospectively, for example, by looking back at archival data of a production process following a device or system failure.

These digital shadows can be used directly by the IIoT asset, other software tools, or people for analyzing results or looking for specific causal relationships. In addition, shadow casters can function autonomously or be driven by requests from outside sources. And the shadows generated by the caster can be stored for future reference and analysis.

Scanning a shadow

A simpler form of digital shadow is based on scanned laser data to create a virtual/visual picture of a real object. While these are often referred to as ‘digital shadows,’ they are used for inherently different applications compared with digital shadows created by caster software. Caster-created shadows are designed for use in analytical processes. Scanned shadows provide non-technical stakeholders and decision-makers with a ‘picture’ of the device or system. They often provide a shadow in a specific context and with sufficient semantic details to enable non-technical individuals to consume and use the inherent data.

Summary

Digital models, digital shadows, and digital twins can be differentiated based on their data flow architectures as well as their intended uses. Digital shadows are more capable than digital models but less capable than digital twins. Various digital shadows have been developed to address specific information needs in CPPS operations and the IIoT. While there is a single digital twin for each system, numerous digital shadows can exist simultaneously. Most digital shadows are produced using casting software, but simpler shadows are sometimes produced using laser scans of physical objects.

References:

A Conceptual Model-based Systems Engineering (MBSE) approach to develop Digital Twins, 2022 IEEE International Systems Conference

A virtual commissioning based methodology to integrate digital twins into manufacturing systems, Springer Production Engineering

An Ecosystem for Digital Shadows in Manufacturing, ScienceDirect

Exploring a Digital Shadow Design Workflow by Means of a Line Following Robot Use-case, Annual Modeling and Simulation Conference

The Concept of Digital Twin and Digital Shadow in Manufacturing, 9th CIRP Conference on High Performance Cutting (HPC 2020)

Towards online adaptation of digital twins, Open Engineering

Virtual Models, Digital Shadows, and Digital Twin Applications in Manufacturing, Simio