If you one day find yourself with a transformer that might or might not have a shorted winding, your first inclination for verifying your suspicions might be to find an inductance meter. The problem with powering up an inductance meter for this situation is that the inductance of a transformer containing a shorted turn might not be much different from that of one that’s fine. Thus a reading on an LC meter might not reveal much about the transformer health.

A better approach is to employ a ring tester. A ring tester for inductors or transformers basically checks the inductor Q. (As a quick review, the electric energy stored in the inductor divided by the energy dissipated during one period.) A shorted turn makes the transformer/inductor more lossy and thus reduces its Q.

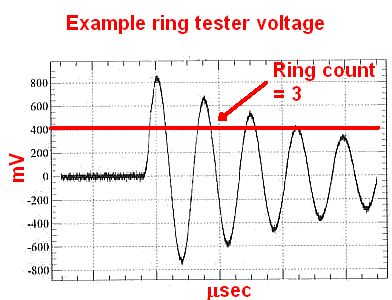

The ring tester checks for Q by applying a pulse to the DUT and then counting the number of cycles in the ringing waveform that results. More specifically, it counts the number of decaying cycles containing energy above a predetermined threshold. The number of cycles above the threshold constitutes a measure of the transformer/inductor Q. Transformers/inductors that are functioning properly will have a high Q; those containing shorted turns, not so much.

It is relatively easy to find DIY circuits for ring testers, and ready-to-go units can be found online for about $60. A point to note, however, is the typical ring tester is designed to handle transformers/inductors as normally found in ordinary linear power supplies, operating in the 50-60 Hz range. That means the ring testers may not work as well for transformers/inductors designed to operate at higher frequencies. Isolation transformers for ethernet lines, for example, are typically specified for 100 kHz frequencies. Transformers used in switching supplies can be designed for frequencies into the megahertz range.

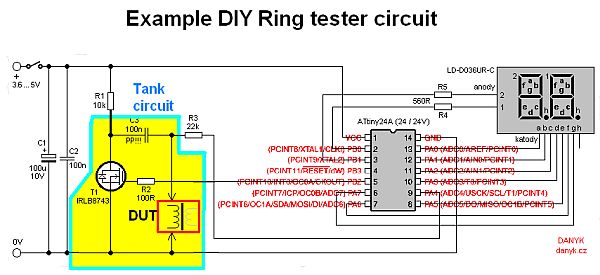

A ring test circuit as devised by a Czech YouTuber.

One DIY ring tester circuit devised by a YouTuber in the Czech republic is built around an Atmel AVR ATTiny24A MPU (ATTiny24, ATTiny24V). The cathodes of a two-digit high-brightness LED display connect MPU PA port while the two common anodes connect to bits 0 and 1 of the PB port. The YouTuber multiplexes the display segments at 100 Hz. He also uses only two series resistors on the anodes (to set display current) instead of one on each segment connection which would be necessary if the digits were multiplexed. The microprocessor is clocked by an internal RC oscillator operating at 8 MHz. The whole circuit is powered by four NiMH AA cells.

In the ring tester the YouTuber describes, the ringing is set up via an RLC series circuit where the transformer/inductor under test is the L. The C component in this arrangement must have a low dissipation factor (tan δ). The YouTuber recommends a good quality polypropylene film capacitor and cautions that a ceramic capacitor won’t work here, and a polyester cap will only work poorly.

Switching takes place via an N-channel logic MOSFET having a low on resistance (on the order of a few milliohms). The on resistance of the MOSFET actually determines the supply voltage necessary (minus the voltage drop of the MPU output) because the supply must be such that voltage applied to the MOSFET gate ensures operation in the low-on-state resistance region. For this reason, the YouTuber suggests a 4.8 – 5 V supply voltage, though a quick look at the MOSFET datasheet (IRLB8743) reveals the on resistance would be slightly lower with a 10-V supply. When the transistor is off (about 130 msec), the tank circuit capacitor charges through the series resistor. When the transistor turns on (about 120 msec), the low dissipation factor capacitor is in parallel with the transformer/inductor L, and damped oscillations commence. They are applied to the PA4 input of the MPU through a resistor, and they are counted. The sequence repeats every 250 ms while the display gets refreshed at a frequency of about 4 Hz.