AC/DC and DC/DC power supplies are normally relatively rugged in normal operation. Nonetheless, there are some protection features built into most of these units to ensure that they do not “self-destruct” or damage associated circuitry – primarily their loads – in the event of a failure or out-of-spec operational mode.

(note: in strict terms, a power supply is either an AC/DC or DC/DC unit, but the latter are also called converters or regulators as well. However, the usage associated with these terms is often sloppy, especially in casual conversation.)

Isn’t a fuse all that is needed to protect the supply and the load?

Yes and no. A fuse protects the supply if the load-path short circuits, or begins to draw too much current. A fuse may not be needed, as many supplies “self-limit” in the sense that they can only supply up to a certain amount of current. A fuse that opens will need to be replaced manually, and this is a problem in many applications (but a virtue on others). Plus, a fuse cannot protect against other types of failure or mis-operation, other than too much current on the output.

- What is Undervoltage Lockout (UVLO)?

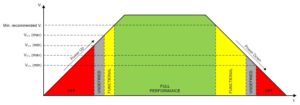

UVLO ensures that a DC/DC converter does not attempt to operate when the input voltage it sees is too low, Figure 1. This is done for two reasons: first, circuitry within the converter may malfunction or act in an indeterminate way if the input DC voltage is too low, and some higher-power components may actually be damaged; second, it prevents the converter from drawing on primary power even if it can’t produce valid output power. This latter aspect means that a source such as a battery that was delivering insufficient voltage to a converter could still be further drained by the converter. As a consequence, the recharge time for the battery will be longer, especially if it from an energy-constrained source such as energy harvesting.

Fig 1: A power supply does not “instantly” come up to full output, but instead has turn-on and turn-off transitional ranges and time; UVLO ensures the supply does not attempt to provide a full output when its input voltage is below the minimum needed for proper operation. (Source: Texas Instruments)

To implement UVLO, a small, low-power comparison circuit within the converter compares the input voltage to a preset threshold, and puts the supply into quiescent mode until the threshold is crossed. To ensure that the UVLO does not chatter around threshold, a small amount of hysteresis is used with it. So, for example, the supply will turn off when the input drops below 5.0 V, but will not turn on until the rising voltage reaches 5.5 V

- What is Overvoltage Protection (OVP)?

Although a supply or converter is designed to normally produce a fixed DC-output voltage, an internal failure in the supply may cause this voltage to rise, and possibly damage the load to which the supply is connected. This failure could be due to a short circuit in a wiring harness, the failure of a passive component, or failure of an active device such as a MOSFET. Regardless of source, it is certainly undesirable by itself, but especially if it also can damage the load. OVP is a function which monitors the output versus an internal reference and short-circuits that output if the voltage rises above the threshold.

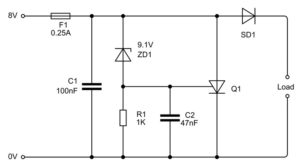

The circuit which monitor and trips is called a “crowbar,” supposedly so named because it has the same effect as placing a metal crowbar across the output. Key to a properly designed crowbar is that it is both simple and that it functions independent of the supply itself, Figure 2.

Fig 2: This crowbar circuit operates form an 8-V supply and has its overvoltage protection set at 9.1 V (this can be changed by using a different Zener diode ZD1 to one with the preferred voltage; at 9.1 V, the Zener diode starts to conducts and causes a trigger signal to switch on the thyristor Q1 (note that the fuse is for protection against excessive current).

There are two kinds of crowbars: one where the crowbar, once tripped, will only be reset if the power I tuned off; and one where it will reset itself once the output-voltage fault is cleared. The second one is useful when the condition which tripped the crowbar is due to some sort of transient rather than a hard failure in the supply. While most supplies now come with a built-in crowbar, many vendors offer a small, separate crowbar circuit which can be added to an existing supply if needed.

- What is thermal overload protection?

By its nature, any power supply generates heat because it is less than 100% efficient. Even an efficient supply generates a potentially troublesome amount: a 100-W supply which is 90% efficient still dissipates 10 W, which is very capable of warming up an enclosure. For this reason, the supply must be designed with sufficient active cooling (such as a fan) or passive cooling (achieved by convection and conductive cooling).

But what happens when the fan fails, or the air-flow path is blocked, or another heat source is introduced into the enclosure? The supply may exceed its temperature rating, which severely shortens its life and may even cause immediate malfunction. The solution is a circuit within the supply which senses the temperature and puts the supply into a quiescent mode if it exceeds a preset limit. As with OVP, some thermal cutoffs automatically allow the supply to resume operation if the temperature drops, and other do not. Which approach is “better” depends on the nature of application and usage cycle.

These are the primary internal protection mechanisms in a power supply or converter. There are also “defenses” against external events and malfunctions which are usually provided outside the supply or as add-on adjuncts.

Reference:

Texas Instruments SLVA769, “Understanding Undervoltage Lockout in Display Power Devices”

Leave a Reply

You must be logged in to post a comment.