The programmable logic control (PLC) is the controller for many industrial processes; it is tightly focused and optimized for the task due to its rugged electrical, software, mechanical, and thermal design.

For engineers and system designers whose design-related work and personal life is focused on smartphones, desktop and laptop personal computers (PC), servers, the cloud, and similar types of technology, the programmable logic controller (PLC) may be an unfamiliar, almost alien unit. The reality, though, is that the PLC is a “workhorse” of industrial process control and production, and for many good reasons. This FAQ will explore the functions, operation, evolution, and history of the PLC, which turned 50 years old in 2018.

Q: Exactly what is a PLC?

A: A PLC is a specialized computer designed to manage the operation of an industrial operation such as a furnace, production line, assembly sequence, bottling/packaging line, and more. A small PLC can be focused on a single small station, while a large one can manage an entire factory line. It is “programmable” in that the user can set it up to implement a specific set of desired steps, and also include conditional operations which are based on logic statements.

Q: What does “programmable logic” mean in this context?

A: The PLC can implement Boolean logic operations such as:

- IF A AND B are TRUE, THEN do D

- IF A BUT NOT B are TRUE, THEN do E

- IF A AND B OR A AND C are TRUE, THEN do F

- IF A AND B are TRUE, WAIT “x” Seconds, THEN do G

- IF A > B is TRUE, THEN do H

where A and, B, and C are on/off conditions (switches or crossing of threshold values), and D, E, F, G, and H are specific actions such as “close valve” or “turn on motor.”

Q: This sounds fairly limiting; is it actually useful?

A: The reality is that a very large proportion of industrial processes can be characterized by these types of logic statements, and entire production lines for complex products such as autos rely on these logical functions for operation (as do small tabletop experiments, as well — but the PLC was not initially targeting these applications).

Q: How was this done before the PLC?

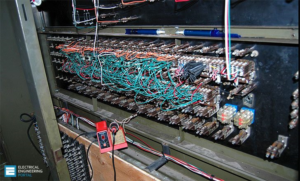

A: It was accomplished with an array of electromechanical relays which were hard-wired, through a patch panel, to implement the desired logic statements, Figure 1. (Remember your basics: relays can be used to provide Boolean logic functions and statements, and even to build flip-flops for one-bit storage, as was demonstrated by some of the earliest computers before and during WWII).

Fig 1: This implementation of a small relay-based controller shows the extent of the complicated set up and “rat’s nest” of wiring. Image source: Electrical Engineering Portal (Image: Electrical Engineering Portal)

Setting up or debugging the array of relays for the desired logic functions was a major task while changing to a new set of instructions was an arduous, time-consuming, frustrating, and error-prone task involving hundreds of patch cords and the patch panel.

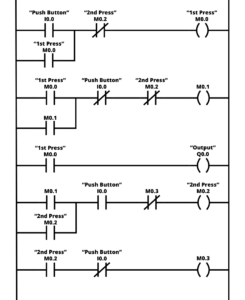

Q: I see the term “ladder logic” used — is this related to PLCs?

A: Absolutely — it is key to the usefulness of the relay-based predecessor and acceptance of the PLC. Ladder logic is a way to document the desired logic operations to which the system is to be “programmed” to implement, Figure 2.

Fig 2: The basic ladder-logic program consists of a series of rungs, each defining a combinatorial logic statement. (Image source: Ladder Logic Academy)

It is inherently graphical and enables visualizing, troubleshooting, and documentation for next person as staffs and shifts change. Knowing how to draw a ladder-logic diagram and read it was an indication of industrial-production literacy and skills.

Q: How did the name programmable logic controller come about?

A: It’s an interesting story. When the PLC was introduced in 1968 (more on this later), it was a called a “programmable controller” or PC. But this was about the time that the personal-computer revolution began, and that latter product usurped the acronym. To avoid confusion and ambiguity, the programable controller became the programmable logic controller, or PLC, Figure 3.

Fig 3: This mid-range PLC is a type used in a wide variety of process-control applications; note the highly functional design and absence of screen or keyboard. (Image: Omron)

Q: What are the advantages of the PLC versus its relay-based predecessor?

A: They are many, and they are significant. First, there’s the reliability, as a relay system is mechanical and so prone to wear out. Even though individual relays are quite reliable, when there are hundreds and thousands of them working non-stop, often 24/7, failure does occur – and they are hard to find and fix. An all-electronic box which is properly designed, with adequate power supply, thermal margin, cooling, supports for vibration resistance, and other ruggedness attributes, has the potential to be far more reliable.

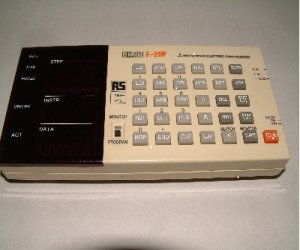

Of course, there’s the programmability. The PLC logic patterns can be modified via software-based programming rather than re-wiring of the patch panel. In the earliest PLCs, this programming was done via a special external box which was connected to the PLC and had basic function keys (not a QWERTY keyboard) and LEDs or a small display, Figure 4. Once the programming was done, this external unit was removed. Over time, the PLC evolved to have an integral user panel, as well as provision for a full keyboard or more sophisticated, dedicated GUI.

Fig 4: This dedicated PLC programmer is typical of the early units, with many dedicated function keys and a multiline display. (Image source: Machine-Information-Systems.com)

Q: What about cost and size, or other benefits?

A: Another major benefit of the PLC versus relays was lower up-front hardware cost, and much smaller size – plus the ability to store and recall programs for later re-use.

Q: Why even consider a PLC, when a PC could be used?

A: There are several reasons, some historical to the time, and some still current.

At the time of the PLCs’ developments, PCs were in their infancy and so had many hardware, application, and operational limitations as well as inherent reliability issues. Storage such as floppy disks (and even tape) was totally unacceptable for the factory floor, and the PLC did not use these. Instead, the PLC had a small, focused, more reliable operating system which was focused on basic operation and the ladder logic, so it did not “crash” and solid-state memory.

To meet the demand for harsh industrial environments, these controllers are designed to be extremely robust, often capable of withstanding extreme temperatures, humidity, vibration, and electrical noise — of which a regular C, and even one which had been enhanced, would find daunting. Cooling fans, for example, would not be acceptable, as they let dirt and dust in and can fail, leading to subsequent failure of the electronics due to overheating.

Q: Is there anything else which made the PLC attractive?

A: First, it was not called a “computer,” as those were associated with marginal reliability in an application which cannot tolerate failure. Also, “computers” – even PCs – needed “computer” people to install, initialize, and operate, and that was incompatible with the factory floor.

Q: What about the software and operating system issues?

A: A regular PC with a conventional operating system is not deterministic. In other words, it is impossible to predict exactly how long it will take to service a given I/O point since the CPU is constantly interrupted by various demands to service the disk drive, memory, comm ports, display, keyboard, and other functions.

In contrast, the PLC was designed to be deterministic. It cycled through all the rungs of the ladder logic in a predetermined, known amount of time, and was not interrupted by other tasks. A complete program may contain thousands of rungs, and they are evaluated in sequence. A complete program scan may take only a few milliseconds for a small ladder, or as long as 100 msec for a longer ladder (in an early PLC); as processor increased in speed, even long ladder could be scanned in the range of ten msec. Regardless of the speed, the process cycle time is known in advance and will not be delayed by I/O activity or other actions. This determinism was a major factor in its acceptance.

Q: But things have changed. Are PLCs still used in place of PCs?

A: Yes, very much so. There are very good at doing what they are intended to do, and their inability to do word processing, play videos, and other things that PCs can do is not a hindrance.

Part 2 of this FAQ will look at the market and evolution of the PLC, as well as its interesting history.

References

- History of the PLC

- The Evolutionary PLC: Past, Present, and Future

- History of Control–History of PLC and DCS

- The concise PLC History

- PLC Timeline

- Programmable logic controller

- The Father of Invention: Dick Morley looks back on the 40th anniversary of the PLC

- Remembering a Manufacturing Legend, Dick Morley

- Control Station, “Dick Morley and the Story of the PLC”

- Control Engineering, “Dick Morley remembered as ‘Father of the PLC’ “

- Allied Market Research, “Programmable Logic Controller (PLC) Market – Global Opportunity Analysis and Industry Forecast, 2017-2023”

- Global Market Insights, “Programmable Logic Controller (PLC) Market Size, Industry Analysis Report”

- Markets and Markets, “Micro and Nano PLC Market”

Leave a Reply

You must be logged in to post a comment.