Researchers from the Mesoscopic Actuators and Systems (MESYS) project group at Fraunhofer Institute for Photonic Microsystems IPMS have been developing novel electrostatic microactuators, so-called nanoscopic electrostatic drives (NED), for three years. Now, this highly interesting scientific approach is being introduced to the public for the first time in an article appearing in the Nature Communications journal.

Prof. Dr. Harald Schenk, Director of the Fraunhofer IPMS and Professor of Micro and Nanosystems at Brandenburg Technical University Cottbus-Senftenberg (BTU), is delighted, “We are very proud of the appreciation of our work and our results being published in this prestigious professional journal. After three years of basic research, we were able to demonstrate a completely new actuatory principle.”

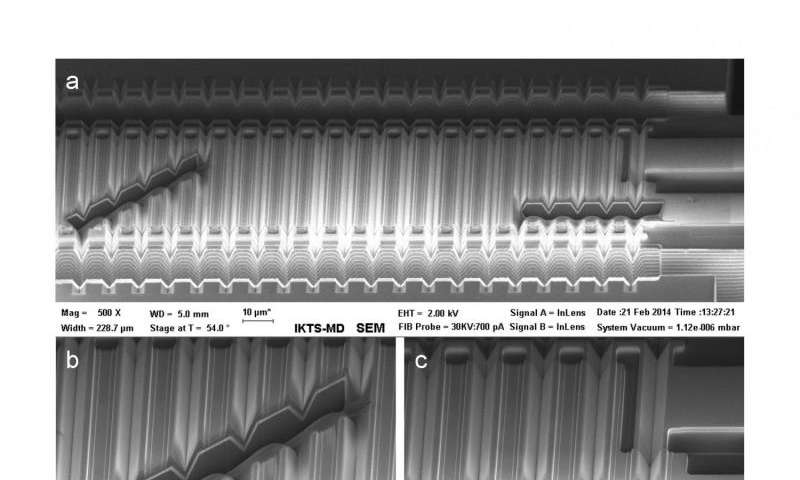

The CMOS compatible actuator class technology developed by MESYS solves fundamental problems of electrostatic actuators. Previously, deflection was very limited due to the so-called pull-in-effects and the movement of conventional actuators was restricted to approximately 33 percent of the electrode spacing. This problem has now been solved. Group Leader Holger Conrad explains, “By means of suitable lever mechanisms, deflections which are much greater than the electrode separations are now available. Therefore, nanometer-small electrode spacings can be deployed, enabling actuators to make use of the enormous force of electrostatic fields.”

The patented actuator class can greatly improve the performance of microsystems such as capacitive ultrasonic transducers, tilting micro-mirrors and microvalves in the future. In addition, the actuator class provides completely new design solutions for microsystems such as micropumps, MEMS loud speakers or micro positioning systems. Conrad concludes, “Our vision is to develop electrostatic actuators with extremely small gap distances for high deflections at moderate control voltages. We want to extend the developed principle to enable in-plane movement and believe that the new electrostatic bender actuators could perspectively replace or supplement piezoelectric or electrostrictive materials as well. This would then allow for RoHs-compliant bender actuators.”