Today, nearly every piece of equipment in a data center has at least one sensor attached to it, and most every facility manager is aware that monitoring systems have the autonomy to send an alert in the event of an abnormality, such as a simple limit breach.

Instead of empowering operators with the confidence to prevent incidents and outages, monitoring systems may actually create a false sense of security. The operations team can get locked into a passive, reactive role—assured that the monitoring system(s) will alert them if there is an issue. Unfortunately, by the time the equipment signals an operator, it is usually too late to take any proactive action. The damage is already done, and the staff is forced into reaction mode or worse: emergency maintenance.

To avoid such unnecessary costs, facility managers must change their position from reactive to proactive to prevent failures before they become an issue. Fortunately, with nearly every piece of equipment connected to a sensor, the opportunity to do so is available.

Increasing the Picture of Awareness

Today, sensor data is typically used to alert an operator when there is an issue. Much less frequently, the gathered data is stored and reviewed throughout the asset’s lifecycle. Looking at performance metrics over a large span of time can reveal insights about how different variables can impact the performance and lifespan of an asset. By adding more data points collected from other identical equipment, abnormal performance patterns will be highlighted more clearly and factually, reducing the need for assumptions.

The more data considered overall, the higher the understanding of various factors’ impact. Environment, surrounding equipment, usage, and maintenance activities all potentially influence performance and the lifespan of assets. Having sufficient observations and data can help distinguish these impacts and identify outlier circumstances that may not be helpful in fostering proactive approaches and predictive modeling.

Data is Meaningless Without Context

Data is not knowledge in itself and must be transformed into useful information in order to provide any insight. One problem with collecting large amounts of data from many different sources is making sense of it and keeping it in context, which requires evaluating how current data relates to other sources of established information. Such context in data analytics enables the development of trends and a deeper grasp of the impacts of the various metrics. Once current and established data and the relationship between them are clearly understood, a predictive model can be defined that takes into account all relevant information. This model will generate more complete information that can enable better decisions.

A Simple Example of Data Insight

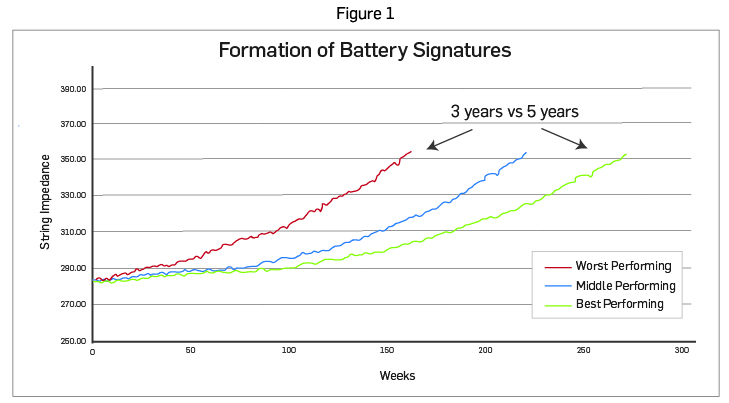

Collecting and reviewing critical battery data every day can provide insight into how batteries are currently performing. For example, when one company’s data is added to nationally gathered data, the performance history can be mapped, and trends become clearer. Then, a standardized lifecycle signature for that make, type, and even the manufacture date can be created. This signature reveals an aging dynamic or battery lifecycle, providing a set of parameters to compare with battery performance and identifying factors leading to reduced quality, shorter lives, and even failures.

Figure 1 shows how the same type of battery can perform differently. By combining the lifecycles of many batteries of the same type, make, etc., a predictive model can be developed that projects remaining useful life. This model must account for factors that might have shortened or extended lifecycles to establish reference signatures that can benchmark performance. With this level of detail, predictive analytics can be used to better manage risk of failure and expedite any warranty claim processes.

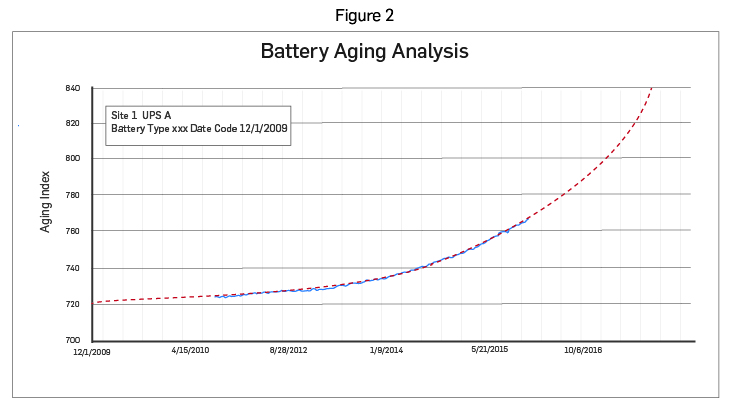

The modeled signature in figure 2 compares actual battery metrics to a standardized aging dynamic or battery lifecycle. In this case, actual performance maps very closely to the reference value. Regardless of correlation to the benchmark values, inputting individual battery data into the predictive model can predict the end of useful life for the battery asset. By mapping the specific battery system data onto the context of the battery lifecycle, a health map for problem identification is created, allowing for more informed decision-making and more efficient operations management. Furthermore, this model brings accuracy to budget forecasting for battery replacements.

Leverage Experts Using Proven Models

While some organizations may collect the data, they likely don’t have the resources necessary to make it actionable. Unfortunately, monitoring systems are not yet intelligent enough to analyze the information collected, so experts must interpret it to extract insight. Failing to consider enough variables or selecting the wrong variable can lead to incorrect decisions and increased business risk. Proper analysis requires specific skillsets that are rarely best performed by data center operators, as they don’t have the time or expertise necessary to do so. As a result, companies are either considering or have already implemented outsourced asset monitoring and management. These focused experts can provide more accurate forecasts and action steps to help plan and manage asset useful life. By partnering with specialized providers, companies have devoted experts maintaining their assets and can focus their internal resources on business priorities.

Get Ahead of the Curve

Predictive analytics enables organizations to gain deeper insights into their operations and function more efficiently. It’s no longer enough to just look and see if a measurement line has been crossed and react to it. Instead, the data can be used to predict an issue in advance. The proliferation of sensors in the data center provides the opportunity to realize a greater awareness of how assets are performing, and predictive models can demonstrate how they will perform in the future. However, in order to create and maintain a predictive analytics platform, organizations must have the right people, processes, and technologies. Creating and maintaining such a platform is not only costly but takes focus away from core business initiatives.

Integrating a predictive strategy into operations can most effectively be accomplished by partnering with an organization focused on predictive analytics with expert resources to accurately interpret data and guide asset management efforts.