State-of-the-art atomic force microscopes (AFMs) are designed to capture images of structures as small as a fraction of a nanometer—a million times smaller than the width of a human hair. In recent years, AFMs have produced desktop-worthy close-ups of atom-sized structures, from single strands of DNA to individual hydrogen bonds between molecules.

But scanning these images is a meticulous, time-consuming process. AFMs therefore have been used mostly to image static samples, as they are too slow to capture active, changing environments.

Now engineers at MIT have designed an atomic force microscope that scans images 2,000 times faster than existing commercial models. With this new high-speed instrument, the team produced images of chemical processes taking place at the nanoscale, at a rate that is close to real-time video.

In one demonstration of the instrument’s capabilities, the researchers scanned a 70- by-70-micron sample of calcite as it was first immersed in deionized water and later exposed to sulfuric acid. The team observed the acid eating away at the calcite, expanding existing nanometer-sized pits in the material that quickly merged and led to a layer-by-layer removal of calcite along the material’s crystal pattern, over a period of several seconds.

Kamal Youcef-Toumi, a professor of mechanical engineering at MIT, says the instrument’s sensitivity and speed will enable scientists to watch atomic-sized processes play out as high-resolution “movies.”

“People can see, for example, condensation, nucleation, dissolution, or deposition of material, and how these happen in real-time—things that people have never seen before,” Youcef-Toumi says. “This is fantastic to see these details emerging. And it will open great opportunities to explore all of this world that is at the nanoscale.”

The group’s design and images, which are based on the PhD work of Iman Soltani Bozchalooi, now a postdoc in the Department of Mechanical Engineering, are published in the journal Ultramicroscopy.

he big picture

Atomic force microscopes typically scan samples using an ultrafine probe, or needle, that skims along the surface of a sample, tracing its topography, similarly to how a blind person reads Braille. Samples sit on a movable platform, or scanner, that moves the sample laterally and vertically beneath the probe. Because AFMs scan incredibly small structures, the instruments have to work slowly, line by line, to avoid any sudden movements that could alter the sample or blur the image. Such conventional microscopes typically scan about one to two lines per second.

“If the sample is static, it’s ok to take eight to 10 minutes to get a picture,” Youcef-Toumi says. “But if it’s something that’s changing, then imagine if you start scanning from the top very slowly. By the time you get to the bottom, the sample has changed, and so the information in the image is not correct, since it has been stretched over time.”

To speed up the scanning process, scientists have tried building smaller, more nimble platforms that scan samples more quickly, albeit over a smaller area. Bozchalooi says that such scanners, while speedy, don’t allow scientists to zoom out to see a wider view or study larger features.

“It’s like if you were landing somewhere in the United States and have no clue where you’re landing, and are told wherever you land, you’re only allowed to look a few blocks around and up to a limited height,” Bozchalooi says. “There’s no way you can get a bigger picture.”

Scanning in synchrony

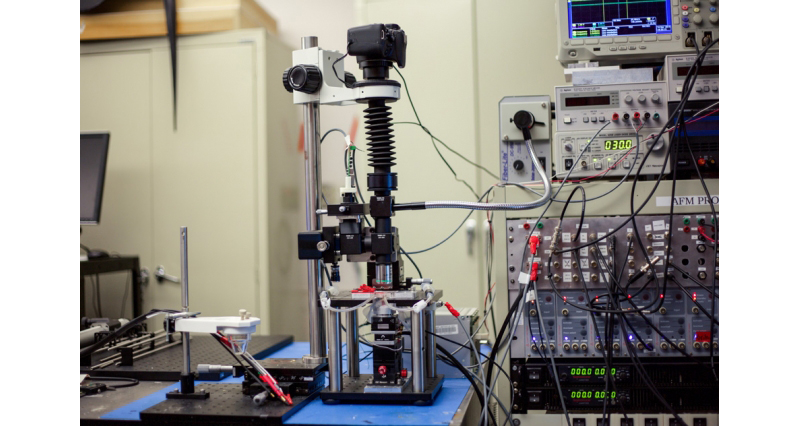

Bozchalooi came up with a design to enable high-speed scanning over both large and small ranges. The main innovation centers on a multiactuated scanner and its control: A sample platform incorporates a smaller, speedier scanner as well as a larger, slower scanner for every direction, which work together as one system to scan a wide 3-D region at high speed.

Other attempts at multiactuated scanners have been stymied, mostly due to the interactions between scanners: The movement of one scanner can affect the precision and motion of the other. Researchers have also found that it’s difficult to control each scanner separately and get them to work with every other component of a microscope. To scan each new sample, Bozchalooi says a scientist would need to make multiple tunings and adjustments to multiple components in the instrument.

To simplify the use of the multiactuated instrument, Bozchalooi developed control algorithms that take into account the effect of one scanner on the other.

“Our controller can move the little scanner in a way that it doesn’t excite the big scanner, because we know what sort of motion triggers this scanner, and vice versa,” Bozchalooi says. “In the end, they’re working in synchrony, so from the perspective of the scientist, this scanner looks like a single, high-speed, large-range scanner that does not add any complexity to the operation of the instrument.”

After optimizing other components on the microscope, such as the optics, instrumentation, and data acquisition systems, the team found that the instrument was able to scan a sample of calcite forward and backward, without any damage to the probe or sample. The microscope scans a sample faster than 2,000 hertz, or 4,000 lines per second—2,000 times faster than existing commercial AFMs. This translates to about eight to 10 frames per second. Bozchalooi says the instrument has no limit on imaging range and for a maximum probe speed, can scan across hundreds of microns, as well as image features that are several microns high.

“We want to go to real video, which is at least 30 frames per second,” Youcef-Toumi says. “Hopefully we can work on improving the instrument and controls so that we can do video-rate imaging while maintaining its large range and keeping it user-friendly. That would be something great to see.”