Researchers from North Carolina State University and Nanjing University have developed an “ultra-thin” sound diffuser that is 10 times thinner than the widely used diffusers found in recording studios, concert venues and movie theaters to reduce echoes and improve the quality of sound. The new design uses less material, which would reduce cost, as well as taking up far less space.

In a typical room with flat walls, sound waves usually bounce off the walls, like light reflecting off a mirror. This creates echoes and overlapping sound waves that result in uneven sound quality depending on where you are in the room.

“Sound diffusers are panels placed on the walls and ceiling of a room to scatter sound waves in many different directions, eliminating echoes and undesirable sound reflections – ultimately improving the quality of the sound,” said Yun Jing, an assistant professor of mechanical and aerospace engineering at NC State and corresponding author of a paper on the work.

But the most widely used diffusers, called Schroeder diffusers, can be very bulky. That’s because the size of a diffuser is governed by the wavelength of the sound it needs to diffuse. Specifically, the depth of a Schroeder diffuser is about half of the wavelength of the lowest sound it needs to diffuse.

For example, a typical man’s voice can be as low as 85 hertz, with a wavelength of 4 meters or 13.1 feet. If that’s the lowest sound the Schroeder diffuser will have to deal with, the diffuser would need to be roughly 2 meters – or just over 6.5 feet – thick.

But the new, ultra-thin diffuser design requires a thickness that is only 5 percent of the sound’s wavelength. So, instead of being 2 meters thick, it would only be 20 centimeters – or less than 8 inches – thick.

“Diffusers are often made out of wood, so our design would use 10 times less wood than the Schroeder diffuser design,” Jing says. “That would result in lighter, less expensive diffusers that allow people to make better use of their space.”

This reduction in diffuser thickness is made possible by the design of the individual cells in the diffuser.

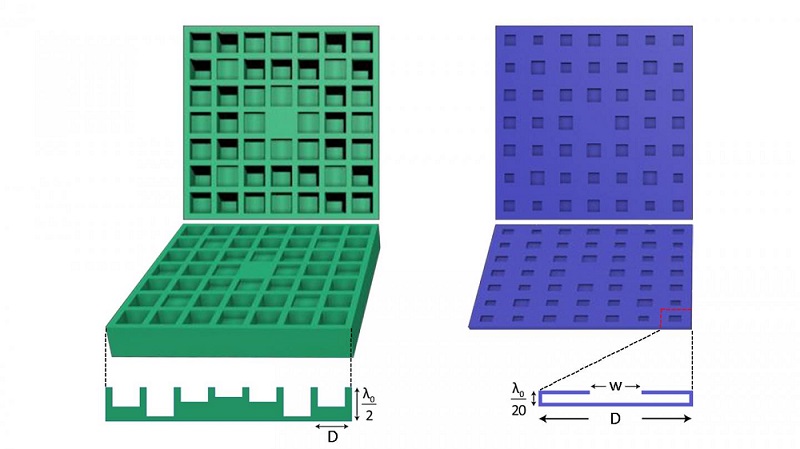

A Schroeder diffuser looks like a panel of evenly spaced squares, which are identical in length and width, but vary in depth.

The ultra-thin diffuser also consists of evenly spaced squares, but the squares appear to be of different sizes. That’s because each of the squares is actually an aperture that opens into a thin, underlying chamber. These chambers all have identical dimensions, but the size of the apertures varies significantly – accomplishing the same sound diffusion as the much larger Schroeder diffusers.

“We’ve built fully functional prototypes using a 3-D printer, and it works,” Jing said. “The design should work just as well using wood.”