The new milk frother you are using to prepare your cappuccino is likely using magnetic gears. Magnetic gears transmit rotary motion like mechanical gears but instead of teeth they use magnetic attraction and repulsion between rotating magnets. Dr Johannes Schönke, a postdoctoral scholar at the Okinawa Institute of Science and Technology Graduate University (OIST), published in Physical Review Applied a theory which extends the possibilities and applications for smooth magnetic couplings, which can produce an even motion without any counterforce. This research has several potential applications in nanotechnology, microfluidics and robotics.

Magnetic gears have several advantages over mechanical gears. The main one is the absence of direct contact between the parts. While mechanical gears, such as the meshing gears inside a watch, transmit the motion through the contact between moving teeth, magnetic gears are contactless. Magnetic gears require less maintenance, no lubrication, they have also better reliability, and efficiency, and they produce lower vibration and noise. Magnetic gears are often based on an alloy of iron, boron and neodymium, which creates the strongest permanent magnets known to date.

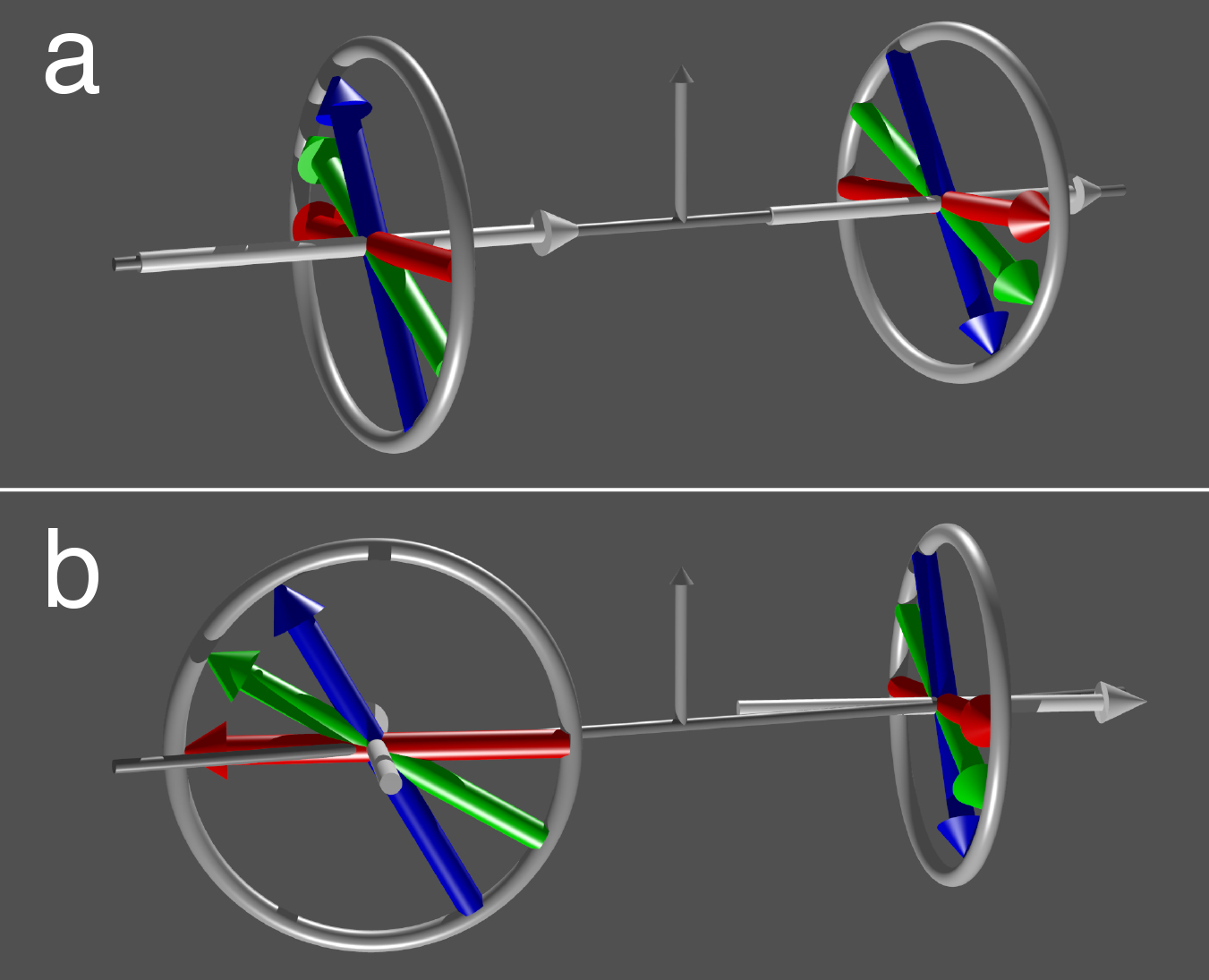

Some of our food mixers in the kitchen, magnetic stirrers in a chemistry lab or other industrial magnetic couplings are based on the idea that the two magnets rotate around the same axis. “I wanted to explore the possibility of positioning the input and output axes at any desired inclination angle,” explains Dr Schönke. “Furthermore, there are certain configurations of the two magnets that allow the addition of a third magnet at a specific position and still maintain a smooth coupling”. As an illustrative example, Dr Schönke modeled a paddle boat where two magnets are connected to the paddles and one to the driving system. If the magnet of the driving system is rotated, the paddles move in a synchronized way to push the boat forward. Interestingly, because of the contactless nature of the magnetic coupling, the paddle axle is fixed outside of the boat, and it does not penetrate the hull. However, the specific triangle geometry between the positions of the three magnets is crucial, to make the coupling work smoothly. In the future, this type of technology is going to be particularly useful in micro- and nanosystems. As for the paddles of the boat model, the motion of mini pumps and valves placed inside micro-channels can be controlled from outside in a contactless way.

The same analogy between mechanical and magnetic gears can be further explored by considering the interaction between a quadrupole and a magnet, each rotating around a specific axis. One way to construct a quadrupole is to place four magnets like a cross, positioned in a way that two north poles and two south poles alternatively face the center. The quadrupole can be thought of as a gear with twice as many teeth as the single magnet. So that when the magnet is rotated by a full cycle, the quadrupole rotates only half a cycle. By rotating the magnet, the quadrupole rotates correspondingly, as it would happen with a mechanical gear wheel mechanism.