Although compressed natural gas represents a cleaner and more efficient fuel for vehicles, its volatile nature requires a reinforced, heavy tank that stores the gas at high pressure and therefore limits vehicle design. Researchers at the University of Pittsburgh’s Swanson School of Engineering are utilizing metal-organic frameworks (MOFs) to develop a new type of storage system that would adsorb the gas like a sponge and allow for more energy-efficient storage and use.

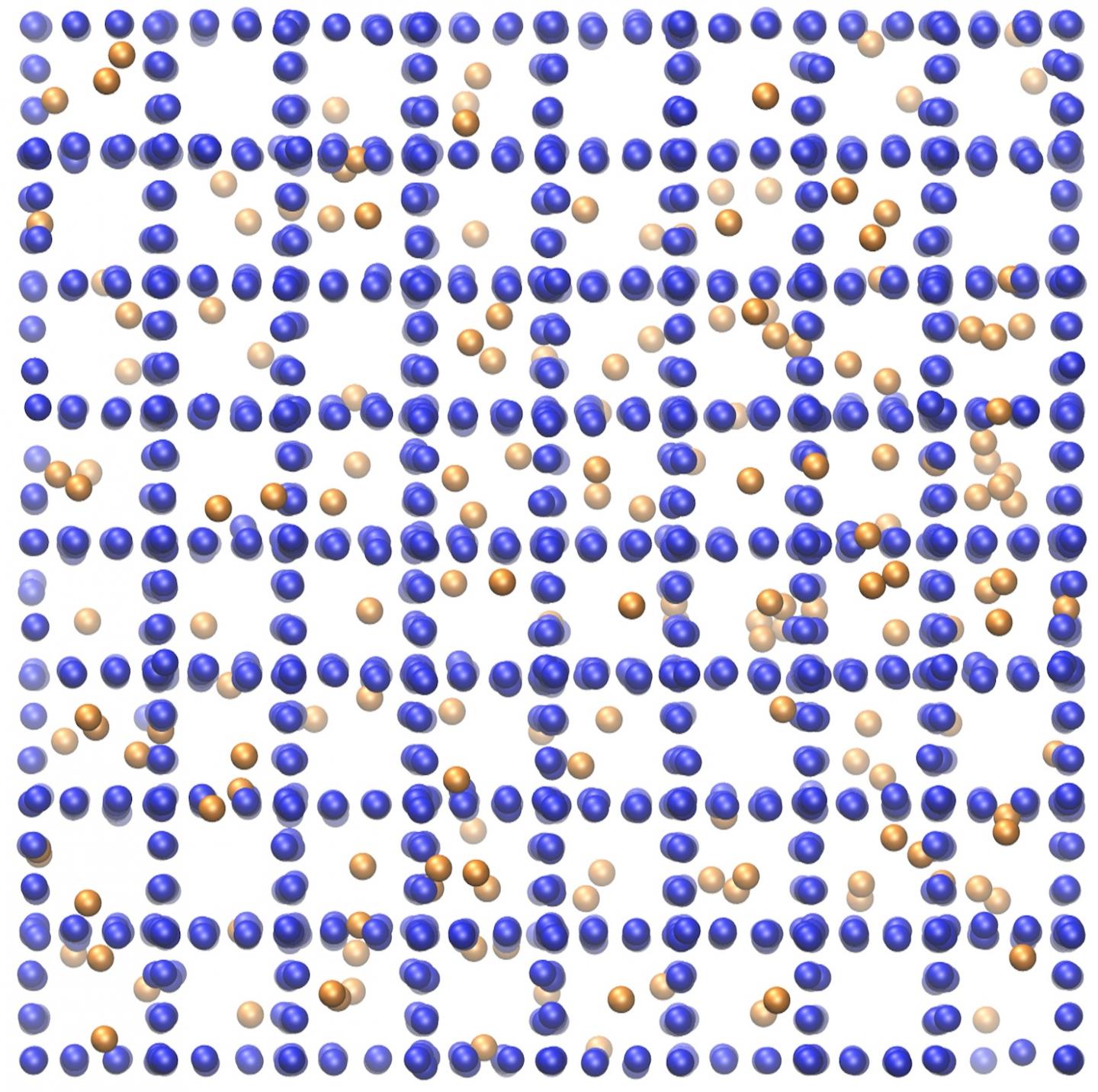

The research, “Mechanisms of Heat Transfer in Porous Crystals Containing Adsorbed Gases: Applications to Metal-Organic Frameworks,” was published this week in the journal Physical Review Letters by Christopher E. Wilmer, assistant professor of chemical and petroleum engineering, and postdoctoral fellow Hasan Babaei. (DOI: 10.1103/PhysRevLett.116.025902) Traditional CNG tanks are empty structures that require the gas to be stored at high pressure, which affects design and the weight of the vehicle. Dr. Wilmer and his lab are instead focused on porous crystal/gas systems, specifically MOFs, which possess structures with extremely high surface areas.

“One of the biggest challenges in developing an adsorbed natural gas (ANG) storage system is that the process generates significant heat which limits how quickly the tank can be filled,” Dr. Wilmer said. “Unfortunately, not a lot is known about how to make adsorbents dissipate heat quickly. This study illuminates some of the fundamental mechanisms involved.”

According to Dr. Wilmer, gases have a $500 billion impact on the global economy, but storing, separating, and transporting gas requires energy-intensive compression. His research into MOFs is an extension of his start-up company, NuMat Technologies, which develops MOF-based solutions for the gas storage industry.

“By gaining a better understanding of heat transfer mechanisms at the atomic scale in porous materials, we could develop a more efficient material that would be thermally conductive rather than thermally insulating,” he explained. “Beyond natural gas, these insights could help us design better hydrogen gas storage systems as well. Any industrial process where a gas interacts with a porous material, where heat is an important factor, could potentially benefit from this research.”

Source: https://www.eurekalert.org/pub_releases/2016-01/uop-prd012016.php