5G Technology World’s video interview with NI’s David Hall looks at 5G ICs coming off the production line and what’s coming next.

As the rate of 5G deployments ramps up, equipment manufacturers need ever more components. Thus, IC manufacturers need to test ICs in production. NI (formerly National Instruments) supplies automated test equipment to IC manufacturers now producing devices such as power amplifiers (PAs), low-noise amplifiers, filters, and the like. 5GTW recently spoke with NI’s David Hall about these devices and some of the problems with 5G that engineers have yet to solve.

NI was one of the companies involved in early 5G research, providing systems for research in activities such as channel sounding. “Back then,” said Hall, “we didn’t even know if mmWave signals would even work.” Figure 1 shows a channel sounder that NI built for AT&T that the carrier would move around cities to learn how 28 GHz signals would propagate in urban areas.

Since then, NI has moved into ATE for testing 5G RF devices that function at both sub-6 GHz and mmWave frequencies. Beamformer ICs are now in use at mmWave frequencies, noted Hall. A single device can contain several inputs that use multistage PAs, phase shifters, and other stages. While beamforming has been used for decades, its use in wireless communications has put a focus on low power, small size, heat dissipation, and low cost.

PAs used in base stations and mobile devices need to improve on power efficiency to make 5G less costly to operate. One such technique to improve efficiently started with LTE is envelope tracking (Figure 2). The technique modulates an amplifier’s DC power so that it operates close to saturation, improving efficiency.

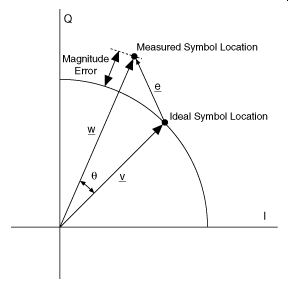

NI recently announced that it has supplied test equipment to Eta Wireless, a spinoff of MIT that uses asymmetric multilevel outphasing to improve PA efficiency. Eta Wireless uses NI equipment to measure error-vector magnitude (EVM, Figure 3) and adjacent-channel power in its amplifiers.

See the complete interview below.