A few guidelines help clarify what three-phase input voltage best suits a particular large power system.

TDK Lambda Technical Marketing

AC-DC power supplies rated higher than 2.5 kW frequently have a three-phase ac input. In the U.S. the voltage can be 208/220 Vac or 480 Vac. In Europe, it is a “harmonized 400 Vac” which really is 415 Vac in the U.K. and 380 Vac for Europe. A higher input voltage allows more power to be drawn from the incoming ac at a lower current. These three-phase ac voltages can be one of two configurations – delta or wye (pronounced “why”).

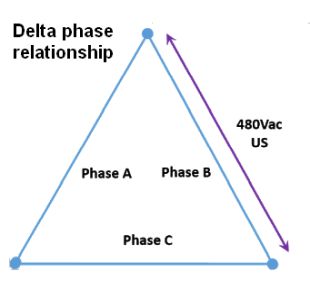

Typically high-voltage power is transmitted from the power generation plants to local substation transformers (where it is reduced in voltage) and then to facilities in a delta configuration. Note that a delta configuration only uses three wires and has no neutral or ground wire. This saves the cost of a fourth wire, which is unneeded during transmission.

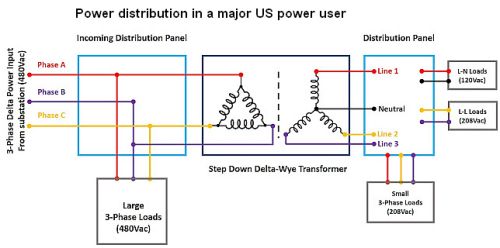

A typical U.S. power distribution scheme for large power users such as factories locates a step-down delta-wye transformer on site. The transformer is generally large enough to sit on its own concrete pad, often outside the facility.

Consider the U.S. first. At a typical large power consumer such as a factory, a 480-Vac delta three-wire feed enters the facility. (It typically comes to the facility from the local utility substation.) From the facility’s incoming distribution panel, 480 Vac delta is supplied directly to electrical equipment needing a large amount of power. Typical loads requiring this much power might include large ovens, test equipment for semiconductors, burn-in chambers, and machines fabricating metal (including laser cutting and additive manufacturing). It is important to note that connecting equipment to this incoming voltage feed, rather than just the reduced wiring gauge, can minimize the size of the delta-wye step-down transformer, cutting costs while saving energy and floor space.

Power for the rest of the facility comes from a second distribution panel. This panel receives input power from a step-down delta-wye transformer that converts a 480-Vac delta configuration to a four-wire 208-Vac phase-to-phase wye configuration. The distribution panel, in addition to being able to supply 208-Vac phase-to-phase, can also supply 120 Vac. The 120 Vac is available by connecting to either one of the output Lines (L1, L2 or L3) and neutral N.

Delta wiring configurations measure 480 Vac phase-to-phase in the U.S.

As a rough order of magnitude, 208 Vac three-phase would be used for mid-sized loads exceeding 5 kW but less than 25 kW. Single-phase 208 Vac is generally for smaller loads exceeding 1.5 kW. The 120-Vac wall outlet can support around 1 kW. The amount of power depends on the wiring size and fusing—consult your local qualified electrician!

Some facilities may also contain a second delta-wye transformer. This transformer provides 277 Vac feeds to lighting and HVAC (Heating, Ventilation and Air Conditioning) equipment. And in Europe the arrangement and voltages are different than in the U.S.

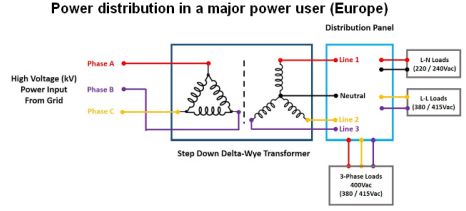

A typical European major power-using facility has its own delta-wye step-down transformer, like its U.S. counterpart, but the outputs are at different voltages.

In European power distribution, the grid provides major power consumers with a high voltage (11 kVac in a delta configuration in the U.K.). A step-down transformer delivers three-phase in a four-wire wye configuration to the facility’s distribution panel. Mainland Europe mainly uses 380/220 Vac while the U.K. uses 415/240 Vac.

Lines coming off the wye step-down transformer connections measure 208 Vac phase-to-phase. Installations obtain 120 Vac by making connections between neutral and L1. In Europe the phase-to-phase wye output voltages are 380/415 Vac (Europe/U.K.) with 220/240 Vac available between L1 and neutral.

The distribution panel, in addition to supplying 380/415 Vac phase-to-phase, can also provide 220/240 Vac through connections to either one of the output Lines (L1, L2 or L3) and neutral N.

Typical three-phase supplies

For examples of three-phase ac-dc power supplies that would work on the distribution systems outlined above, we shall review some examples from TDK-Lambda’s product offering. The HWS1800T-24 is a 1.8-kW-rated power supply accepting a 170-265 Vac three-phase input. This kind of input would be suitable for operation from a standard U.S.- type of 208-Vac three-phase wye input. It could also operate in Europe but would require a 400-to-220 Vac three-phase wye-wye step-down transformer.

The TPS4000-24 is a 4-kW-rated power supply accepting a 350-528 Vac three-phase input, either delta or wye. This supply would be suitable for operation in the U.S. and in Europe without changing connections to the power supply or additional transformers.

The Genesys+ series of programmable power supplies encompasses a large number of models ranging from 1.5 kW to 15 kW. Depending on the power level, the units have different input voltages covering most of the global input voltages.

An HWS1800T-24 three-phase power supply.

Regardless of the supply maker, there are a few points users of three-phase supplies should keep in mind. Ensure the manufacturer has internal fuses fitted, as some low-cost power supplies do not. A high-voltage fuse is required for each phase. They are bulky and are not inexpensive.

With these points in mind, users of three-phase supplies might be tempted to take a second glance at those big grey mystery boxes – which you’ll now understand are step-down transformers — surrounded by chain-link fencing and high voltage warnings in the company parking lot!