Integrated smart power modules will run mechanical loads that would

otherwise sap fuel mileage.

THOMAS YIM | ON SEMICONDUCTOR

GOVERNMENT REGULATIONS are stimulating demands for more economical vehicles that produce not just fewer NOx pollutants, but also less CO2. Vehicle tax policies currently favor less polluting models, and car makers must cope with new legislation such as the EU average fleet emissions directive which dictates the average CO2 emissions of all cars must not exceed 130 g CO2 /km. Non-complying manufacturers must pay an excess emissions premium on every unit sold. The CO2 limit will be reduced to 95 g/km by 2021 and to even lower levels as time goes on.

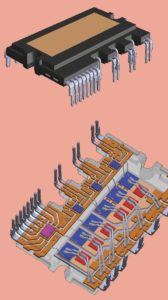

The DBC (direct-bonded copper) substrate, as depicted on these chip package drawings, enables economical and efficient thermal management.

An important part of the strategy for meeting such demands is to replace major subsystems usually driven by the engine with electrically-driven alternatives. Water pumps, oil pumps, air-conditioning units, turbo chargers and power steering systems have all been candidates. Reducing mechanical loads on the engine lets more fuel go toward powering the wheels. Replacing mechanical motor loads such as pumps, fans, compressors with an electric unit could reduce fuel consumption by as much as 3 to 5%.

The automotive industry is keen to ensure that the replacement electrical systems are as efficient as possible. Another concern is how proliferating electrically-driven systems may grow the size and weight of vehicle wiring harnesses. Car makers must prevent harnesses from becoming excessively large and heavy.

Additionally, electrical systems replacing mechanical functions will make heavy use of high-power motor drives. Here, the automotive industry can benefit from experience from other industries. In domestic appliance markets, for example, energy-efficient motor drives have been of paramount importance for years. Product-labeling schemes that let consumers compare energy ratings have focused attention on efficiency and enabled informed buying decisions.

The cost of energy-saving variable-speed drives has come down with advances in power-semiconductor technologies and the maturing of intellectual property like Field-Oriented Control (FOC) firmware. Use of variable-speed drives has gradually filtered down from high-end equipment into mainstream products. One result has been appliances that cost less to run, are quieter, and are more versatile.

Motor drives that are quiet, as well as highly efficient, are increasingly important for the automotive industry. As vehicles become more electric and adopt stop-start (micro-hybrid) operation to save fuel in combustion engines, vehicle cabins are becoming progressively quieter. Consequently, mechanisms like electric motors must also become more silent so they don’t annoy passengers.

Variable-speed control isn’t just make electric motors more efficient. It also brings the opportunity to adjust oil and coolant flow rates over a wide range of engine operating conditions. For example, suppose an engine has been running at high speed but then idles as the car waits in traffic. A conventional water pump will slow down when the engine does. In contrast, an electronically controlled variable-speed pump can be programmed to move coolant at a rate determined by the thermal conditions inside the engine. It can also continue running after the engine has switched off to optimize the engine cool-down profile.

The main power circuit in a variable-speed drive is basically an inverter. And drives with inverters are more complex than simple fixed-speed drives. They comprise a controller that runs the FOC algorithm, high-side and low-side gate drivers for the power-transistor bridge driving current into the motor phases, up to six IGBTs or MOSFETs in a three-phase bridge, and protection against potentially destructive hazards such as voltage surges, short-circuit currents, and excessive temperature.

Modern control modules for motor drives have a high level of integration that lets automakers save space, boost reliability, and keep down costs. And lessons learned with motor drives for the appliance industry have helped advance the trend. For example, Intelligent Power Modules (IPM) created originally for appliances take advantage of state-of-the-art fabrication and packaging technologies to combine high-voltage, high-power circuitry with logic circuitry all in the same device.

An IPM integrates the high-voltage power silicon of the bridge in the same module as the gate drivers and protection circuitry. This integration has several advantages for motor-driven systems. For one thing, the modules have low thermal resistance because their circuitry sits on direct-bonded copper (DBC) substrates. Obviously, high integration also simplifies the design of the power stage – the circuit topology inside the IPM is not trivial.

Moreover, it is space-efficient to concentrate all the driver power-stage circuitry in a single module. The module can occupy a smaller footprint and also typically will weigh less. It has a high reliability because there are fewer individual components to be placed and connected.

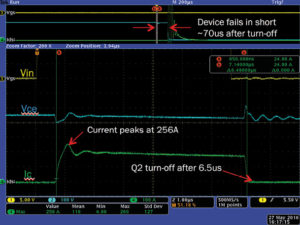

A screen-grab of a FAM65V05DF1 power module in operation illustrating the short circuit rate condition: Vdd=450 V,Vcc=15 V Tj=150⁰C. Three individual single-channel high-voltage ICs control the gates of the high-side IGBTs. A single low-voltage IC with three output channels controls the gates of the low-side IGBTs.

Recently, ON Semiconductor’s FAM65V05DF1 Auto IPM Smart Power Module became available. It is an automotive-qualified (AECQ100/101) integrated power module containing a three-phase bridge comprising six power switches that each combine a 650-V high-efficiency IGBT and a freewheeling diode having soft recovery characteristics and a low reverse-recovery current. The IGBT’s 650-V rating allows operation from a bus voltage of up to about 400 V with adequate safety margin. This high-voltage capability is important because the industry increasingly contemplates using high-voltage buses to distribute power to electrical loads at low current.

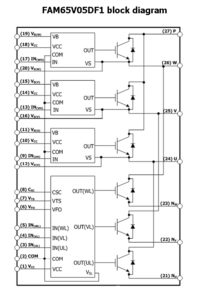

Three individual single-channel high-voltage ICs (HVICs) control the gates of the high-side IGBTs, and a single low-voltage IC (LVIC) with three output channels controls the gates of the low-side IGBTs.

The LVIC and HVICs in the FAM65V05DF1 implement individual under-voltage lockout (UVLO) circuitry to protect the IGBTs against operation with too little gate-driving voltage.

The FAM65V05DF1 block diagram illustrates the integration of three HVICs, a three-channel LVIC and power semiconductors.

Over-current protection circuitry is implemented in the LVIC, with a soft turn-off feature that protects IGBTs from potentially damaging voltage surges by decaying the gate voltage instead of turning the devices off abruptly. The module’s temperature sensor, used to coordinate thermal protection, is also integrated in the LVIC. In addition, the LVIC has a fault output, which can be used to activate system-level protection for optimum reliability.

For automotive use, module thermal performance is extremely important. Peak ambient temperatures can be high, especially for modules sitting near the engine.

Size and cost constraints must also be taken into consideration. A DBC substrate is economical and thermally efficient. In the Auto IPM, the IGBT and freewheeling diode dies attach directly to the DBC substrate. This ensures efficient routing of heat away from the power dies to the edge of the package, where a heatsink can aid dissipation.

Bringing power semiconductors, drivers and protection circuitry together in a single module has enabled the realization of a complete three-phase bridge and driver in a footprint of just 44 × 26 mm. This represents a 30% saving in PCB space compared to a conventional controller implemented using individual automotive-qualified components (discrete IGBT + external three-phase gate driver, etc.).

In a nutshell, energy-efficient integrated high-voltage power modules help eliminate power-sapping mechanical actuators typically driven by the engine crank. Field-stop-trench IGBTs, STEALTH diodes, HVIC, LVIC and DBC technologies are the major enablers for this new generation of auto IPMs.