A digital twin (DT) generally refers to a digital representation of a physical object, system, or process. The idea of creating a DT is to replicate a real-time model of a physical entity. While trying to make a real-time model, the various aspects of the physical entity, such as properties, behavior, and status, are considered.

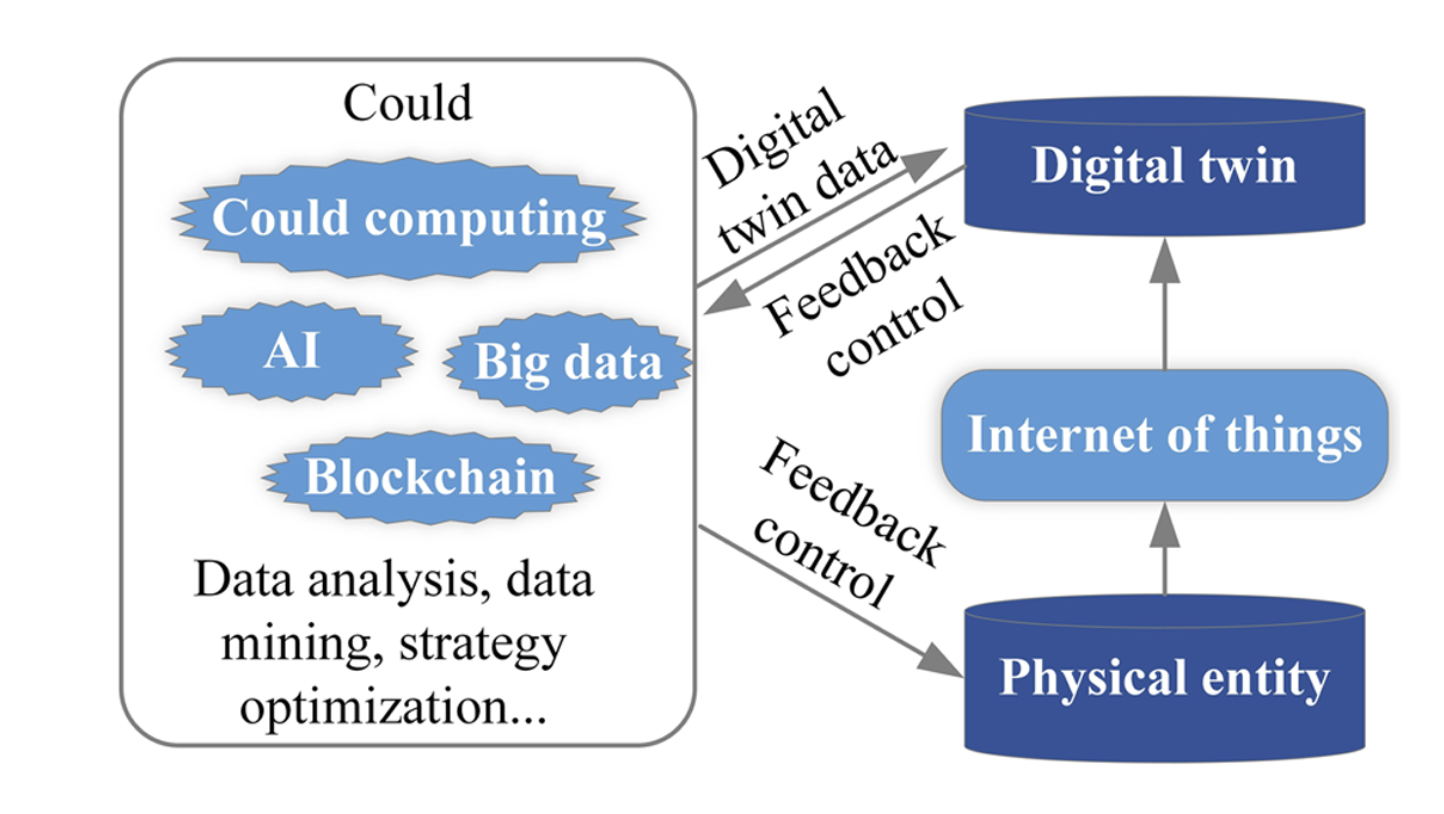

DT as a concept has arrived after the emergence of technologies such as the Internet of Things, big data, artificial intelligence, and smart systems, to name a few. Figure 1 shows how DT is linked with other emerging technologies. This concept has revolutionized industries such as manufacturing, healthcare, and transportation, offering new opportunities for efficiency, innovation, and problem-solving.

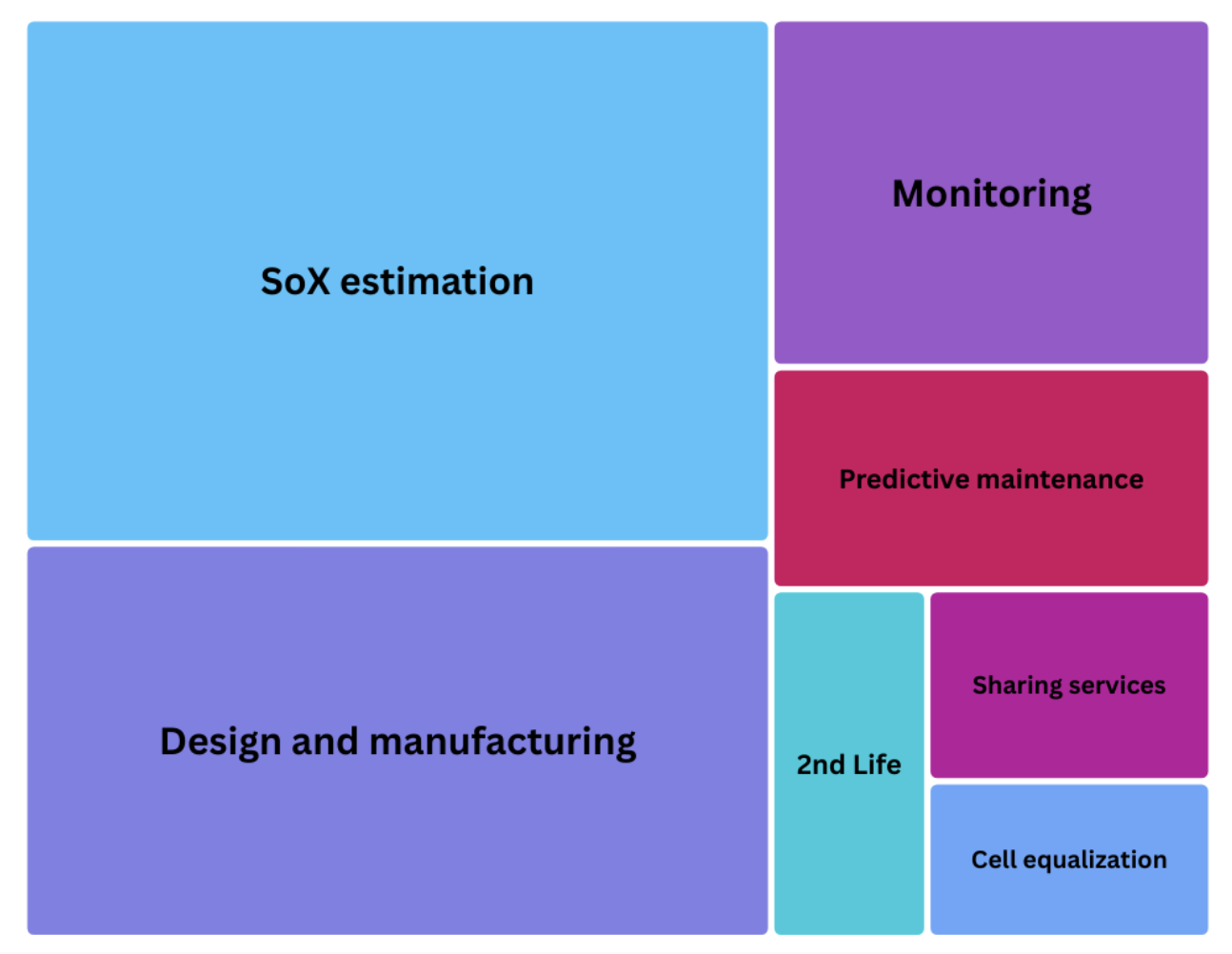

When it comes to the field of electric vehicle technology, DT is relevant in the field of battery management systems (BMS). DT can help solve some pressing challenges in the battery industry, such as longer charging times, faster degradation, and fault diagnosis. Let us review the specific cases of DT within the BMS, which are as follows:

State-of-X (SoX) estimation and processing

SoX in a battery system refers to the various measurable parameters of a battery, including state-of-charge (SoC), state-of-energy (SoE), and state-of-health (SoH). The SoX parameters are essential to understanding the complete characteristics of a battery. These parameters are the input to many algorithms carried out in a BMS, in particular, and EV, in general.

The current issue is that an EV’s BMS has a space-limited microprocessor. They cannot handle and process large amounts of data. Therefore, a possible solution is connecting the BMS to cloud technology to process large amounts of data on a remote high-end processor.

Advanced fault diagnosis

The inability to store a large amount of data also means that the BMS may not have access to past data where several fault events may have appeared. As such, DT can utilize state-of-the-art algorithms to understand the pattern of faults based on historical data stored in the cloud.

This can enable the BMS to perform advanced fault diagnosis and predict potential faults before they occur. Additionally, by analyzing the historical data in the cloud, DT can identify any recurring patterns or trends in the faults, allowing for proactive maintenance and optimization of the BMS performance.

Battery design optimization

With the help of DT, it is possible to share the battery performance with multiple stakeholders. These stakeholders include the quality cell and the inspection cell, to name a few. The simultaneous presence of real-time data for all the stakeholders means that batteries can be optimized for several parameters to improve their performance.

This optimization process can involve adjusting factors, such as cell chemistry, charging algorithms, and temperature management, to maximize battery life and efficiency. By utilizing DT algorithms, manufacturers can analyze historical data on battery faults and failures to identify patterns and develop strategies for preventing future issues.

Battery swapping services

Battery swapping services are identical to gas fuel stations, where the vehicle is refilled with fuel. Battery swapping tackles the problem of long charging hours. But when the batteries are swapped continuously, it is crucial to know the status of the incoming and outgoing batteries. As such, DT can leverage IoT technology to inform consumers and service providers about the battery status.

This real-time information can help consumers make informed decisions about their battery usage and allow service providers to efficiently manage their battery inventory.

Additionally, IoT technology can also enable predictive maintenance for batteries, helping to identify potential issues before they occur and minimizing downtime for both consumers and service providers.

Vehicle-to-grid (V2G) integration

V2G is a possible solution for addressing grid power congestion during peak hours. DT can help exchange the data with the grid operators to identify the ideal time to charge and discharge EVs. By integrating V2G technology, DT can facilitate a two-way flow of electricity between EVs and the grid.

This allows for more efficient utilization of renewable energy sources and helps stabilize the grid during high-demand periods. Additionally, DT can provide real-time data on EV battery levels and availability to grid operators, enabling them to optimize charging and discharging schedules for maximum efficiency.

DT models need physical models of all battery parts at different scales. The models refer to various parameters, such as electrical, physical, and thermal. As batteries evolve, new parameters are expected to be added. But the point is that these models should be established independently so that all these individual models can be collectively put into a DT. Some specific cases of DT may require different combinations of models with variations in the weightage of each model.

Summary

DT is a generic concept that can be applied to any technology field. The advent of this idea is due to the rise of other technologies such as artificial intelligence, big data, machine learning, cloud computing, and the Internet of things. DT has significant relevance to BMS as a digital representation of a battery. It can be connected to the actual battery system, and dynamic changes can be made to improve the performance of the batteries.

However, DT is still under development, and further research and development is needed to standardize this concept.

Leave a Reply

You must be logged in to post a comment.