Part 1 looked at basic AC and DC motors which do not require “electronics” to operate (although the variable-frequency AC motor is an important exception). However, the development of fast, low-resistance all-electronic switches – primarily MOSFETs as well as IGBTs – and microcontrollers, plus powerful permanent magnets has dramatically changed the situation.

Q: What is an EC (electronically commutated) motor?

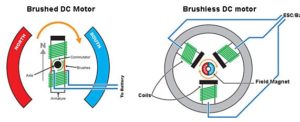

A: An EC motor, often called a brushless DC (BLDC) motor, is just that: a motor which operates from the DC supply but doesn’t have brushes. It operates using an arrangement where the stator has a set of fixed windings, and the rotor has permanent magnets, Figure 1. The current in the windings is controlled by the electronic switches, which are turned on/off via the gate drivers which are controlled by the system processor. There are no brushes, so the issues of brush wear, sparking, and dust do not exist.

Fig 1: The brushless DC motor (right) uses rapid, sequential switching of the poles to rotate the magnetic field, which causes attraction/repulsion with respect to the rotor permanent magnets; this is in contrast to the physical commutation of the filed in the brushed motor (left). (Image source: Think RC/JP Commerce, LLC)

Q: What are the attributes of the EC approach?

A: There are many. First, the speed can be set and controlled as needed by changing the rate at which the switches are commutated. It operates effectively across a wide range of speeds with rated load, and is capable of reaching a higher speed range and lower noise generation. Efficiency is high, and there is a high ratio of output power to size;

Further, if a shaft sensor is added to measure the motor speed, via tachometer or encoder, then a feedback loop can be used to keep the speed at a desired value regardless of load and other shifts.

Q: Are these the only advantages?

A: No, there are many others. The EC motor can be very efficient overt a wide range of speeds and load situations since control is done by a “smart” controller. Further, this control can invoke different performance profiles to match application needs. For example, it can provide a smooth start/stop profile to avoid sudden acceleration/deceleration, or use an S-curve profile to provide both smooth transitions along with high speed. The smart control allows tailoring the motor performance to the application priorities.

Q: How does the EC motor relate to the stepper motor?

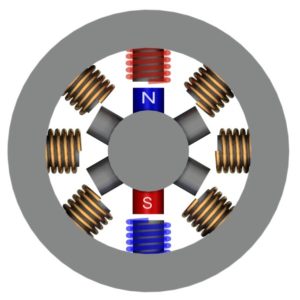

A: A stepper motor is a specialized EC motor. It has a large number of poles around its periphery, and corresponding permanent magnets on its rotor, Figure 2. When the poles are energized as directed by the controller, the rotor “steps” to the next position; it can stop and hold there (a very useful feature) or be directed to go the next pole and thus rotate (up to modest speeds), one step at a time.

Fig 2: A stepper motor has many pole pieces around it’s periphery, by energizing them in forward or reverse sequence, the rotor is directed to step to a desired location where it can then stop or be directed to continue. (Image source: ManufacturingET.org)

While stepper motors are not a good fit for high-speed, continuous-rpm situations, they are often an excellent choice for precise, stop-and-go/hold positioning. They typically offer as many as 256 steps/revolution, and if that resolution is not enough, an advanced technique called “microstepping” allows the controller to move the rotor to positions between the physical steps.

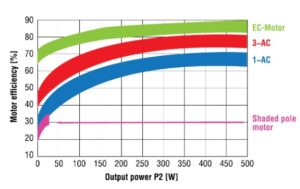

Q: What is the comparative efficiency of the AC, DC, and EC motors?

A: While each motor can provide moderate high efficiency at a target load and speed, the efficiency of the EC motor is generally the highest of all, Figure 3.

Fig 3: While each motor has a band of efficiency depending on specific design, application, load, and other factors, this graph shows the relative efficiency between the EC motor and its closest competitors, the single-phase and three-phase AC motor. (Image source: EBM Papst)

Further, its efficiency remains high across a wide load and speed range, which the AC and DC motors cannot do this (except for the AC VF motor). Although numbers vary, an AC motor will typically have efficiency between 25 and 50%, a DC-brushed motor can be in the 60-80% zone, and an EC motor can reach 90%. Of course, efficiency is not the only figure of merit for a motor, nor is it always the top one, as one (or more) of the many other parameters may be more critical.

There are thousands of motor-related references available online, ranging from highly academic, analytic ones which focus on theory and equations (all very important), to functional descriptions with modest amount of theory, to practical, hands-on articles and papers. A few are listed below.

References

- EBM Papst, Appliance Design, “EC Motors, Explained”

- Motion Control Online, “Brushed DC Motors Vs. Brushless DC Motors”

- Lessons In Electric Circuits, “Chapter 13–AC MOTORS”

- com, “What is a Variable Frequency Drive?”

Leave a Reply

You must be logged in to post a comment.