The Luneburg lens is an extremely efficient reflector of radar energy based on advanced principles and fabrication techniques.

The theoretical Luneburg lens requires a smooth, continuous gradient of the refractive index from the center to the outside. In practice, this is generally not a viable type of construction (but that is changing).

Q: What is done to build a practical lens?

A: Theoretically, to have smooth bending of the incident ray, many concentric shells are required. In practice, Luneburg lenses are built of layered structures of a smaller number of discrete concentric shells, each of a different refractive index. These shells form a stepped refractive index profile that differs slightly from Luneburg’s ideal solution. Fortunately, even a few concentric shells can provide acceptable performance.

Q: Are these lenses standard, off-the-shelf items?

A: Yes, they are. For example, Rozendal Associates, Inc. (Sunnyvale, CA) offers lenses with diameters from two to thirty-two inches as catalog items and has the tooling for manufacturing stepped index lenses up to forty-eight inches in diameter (Figure 1).

Another provider is Aresia (Villeneuve la Garenne – France) who also offers any sizes, designed for internal mounting (Figure 2).

QinetiQ (Ashford, Kent, United Kingdom) manufactures these lenses and also incorporates two of their own 7.5-inch units into their Banshee Whirlwind™ remotely piloted aerial target (Figure 3).

Q: Are multilayer stepped-index lenses hard to make?

A: Yes and no. It depends on the final size and the number of discrete layers involved. There are challenges and constraints when making the stepped-gradient lens, as each layer must be formulated with a material with a different refractive index.

Q: Is there a new approach offering an alternative manufacturing solution?

A: Yes, 3D printing (additive manufacturing) is offering new options for making these lenses, doing it more quickly and closer to the ideal concept. It can be used to create thin layers of different refractive indices by varying the formulation as each layer is added. These layers can be thin, building up the lens like an onion.

Q: Who is doing this?

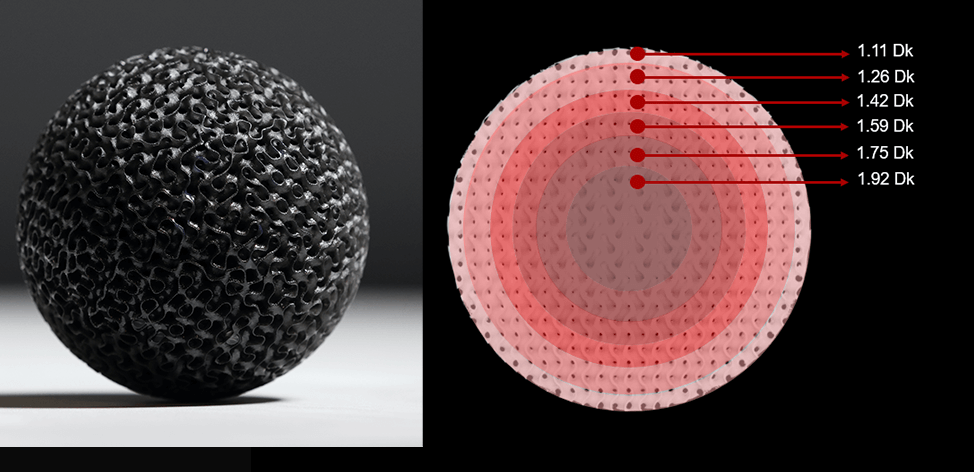

A: Fortify, Inc. (Boston, MA), a digital manufacturing company, provides patented hardware designed for high-viscosity composite materials with the capability to magnetically align material fibers to architect the end-part properties. In collaboration with Rogers Corporation, they have developed multiple low-loss dielectric materials for use in high-bandwidth, high-frequency radar, and communications systems and components (Figure 4).

These materials consist of a unique low-loss polymer blended with specialty dielectric ceramic additives to create these high-performance dielectric materials. Note that these materials require unique 3D printers, not the standard ones generally used for most prototyping and production with various plastics and metals.

Q: Is the Luneburg lens related to a gradient index (GRIN) lens?

A: They are related in that they both have an index of refraction which varies continuously with distance from an index point. The GRIN lens is usually fabricated as a microlens with a radially varying index of refraction that causes an optical ray to follow a sinusoidal propagation path through the lens. It combines refraction at the end surfaces along with continuous refraction within the lens. The index of refraction changes gradually, altering the path, speed, and direction light takes through the lens.

GRIN lenses are generally used to collimate or reimage the output of an optical fiber. Typical applications include coupling the output of diode lasers into fibers, focusing laser light onto a detector, or collimating laser light (note that the light-bending gravitational-lens phenomenon of a star is a GRIN-like lens, as the bending due to the star’s intense mass and gravity decreases uniformly with distance from the star — quite a contrast in scale to the microlens!).

Q: What else can you do with a Luneburg lens?

A: The lens has applications beyond use as a high-performance retroflector and RCS enhancer. For example, it can be used in the Luneburg lens antenna, where the antenna radiates the beam in any direction from a feed located opposite the beam.

Q: What are the advantages of this antenna?

A: The scanning beam can be moved around the sphere very rapidly since the feed is relatively lightweight, in contrast to a parabolic-dish antenna where the entire dish must be moved. Also, as the Luneburg lens is spherically symmetric, a single lens can be used with several feeds looking in different directions, again unlike parabolic reflectors where the feeds must be located at a single focal point.

Many smaller parabolic antenna arrays have been replaced by electronically scanned phased arrays, which offer near-instantaneous electronic movement. Of course, they do not have the gain of a large parabolic dish, so physically steerable dish antennas are still used.

Conclusion

The Luneburg lens is a passive RF device that enhances RCS and radar visibility based on advanced mathematical concepts and ray tracing. It is used to temporarily enhance the radar-return energy for test or tactical purposes. These lenses can be bought as standard items, while 3D printing using specialized RF polymers is offering new ways to fabricate them more closely to their ideal principles.

Related EE World Content

Device Turns Flat Surface into Spherical Antenna

Lens antennas focus multiple wireless beams

Improved estimation of automotive radar signal strength

Evolving radar technology in ADAS

How many types of radar are there?

Metamaterials, mmWave antennas, 3D radar and holographic beamforming

Understanding decibels and decibel measurements

The why, where, and how of automatic gain control, Part 1

External References

The Aviation Geek Club, “How Luneburg lens radar reflectors are used to make stealth aircraft visible on radar screens”

3DFortify, “3D Printing for RF & Microwave Devices”

Fortify, “State-of-Technology Update On GRIN/Luneburg Dielectric Lenses/Antennas for Microwave/mmWave Applications”

Wikipedia, “Luneburg lens”

Rozendal Associates, “Luneburg Lenses”

RF Wireless World, “Advantages of Luneburg Lens | disadvantages of Luneburg Lens Antenna”

Mayurakshi, “Luneburg Lens”

Military Embedded Systems, “Radar cross section: The measure of stealth”

MIT Lincoln Laboratory, “Introduction to Radar Systems: Target Radar Cross Section”

RF Cafe, “Radar Cross Section (RCS)”

West Marine, “Selecting a Radar Reflector”

National Boating Safety School (Canada), “Boat Radar Reflector Requirements”

ITU, “Technical Parameters of Radar Target Enhancers”